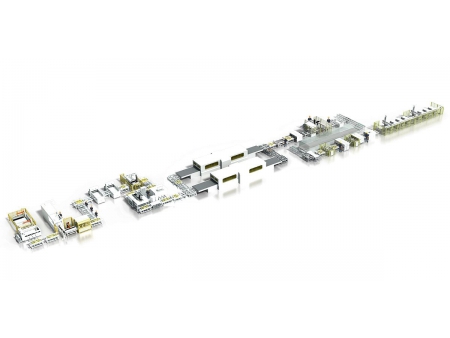

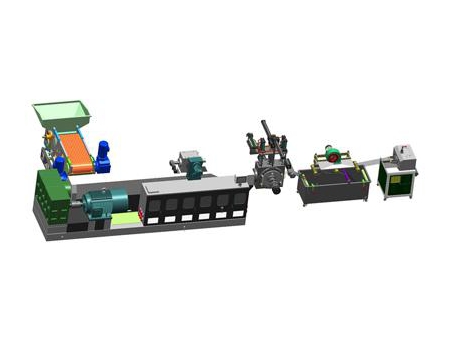

EVA Extruder Pelletizing Line

Request a Quote

Rubber Pelletizer/ Pelletizing Equipment/ EVA extrusion Equipment

Public Project Condition

- Public Project Condition

- Water demand Water temperature:≤38℃

- Industrial soft water(non-ionized water ) water temperature ≤38℃

- Circulating water: for barrels cooling; using soft water(distilled water) to prevent scale

- External circulating water: for cooling internal circulating water and water trough

- Water supply suggestion: build pool 25~30m3outside of workshop and pump the water

- Industrial soft water(non-ionized water ) water temperature ≤38℃

- Ambient condition for electric cabinet: Conductive dust free; Temperature:≤38℃

- The full set equipment is placable on rigid flat ground, without extra base

Processing introduction

- Machine color:main frame:gray cabinet color:computer color

- Pelletizing craft

automatic conveyer----Double-awl feeder---∮120 Single screw extruder---Hydraulic Screen Changer—Water cooling dia face hot cutting--- centrifugal dehydrator--- vibrator screen –Silo

Technical Parameters

- Kneader: Customer owned

- Auto reversing elevator : 1set

- Feeder material motor power :2.2kw

- Limit switch limits up and down

- Elevator hopper is SS material,

- Convey the material to conical double screw force feeder

- Feeder material motor power :2.2kw

- Double-awl feeder: 1 set

- Motor power: 11kw, using TECO frequency converter

- Feeder screw: 2 PCS, Nitrogen & chromate treatment, burnished surface.

- Body : polishing treatment inner side . hard chromate treatment.

- Hopper : polishing treatment inner side . hard chromate treatment.

- Motor power: 11kw, using TECO frequency converter

- KSD-120 extruder Gear box

- Y2 type level 4 AC motor

- Power:75kw

- main motor rotation speed:1480rpm

- Adjust Speed Method: adopting "TECO" AC frequency conversion speed

- Diameter:φ100mm

- L/D:15:1

- Applying Cold water cooling for Screw barrel

- material is 38CrMoALA Nitrogen treatment, high temperature vacuum quench treatment;hardness:HRC60-64;Screw element is made by the surface forming grinding through machining center.

- material is 38CrMoALA Nitrogen treatment, high temperature vacuum quench treatment;hardness:HRC60-64; Screw element is made by the surface forming grinding through machining center.

- Barrel is air cooling.

- Barrel has the protective cover.

- screen exchanger:

(1) Position: fixed between barrel and head

(2) Plate filer automatic screen exchanger,Flow section for circular

(3) Casting copper heater 2 slices.

(4) The double location:Including two pieces of porous plate - hydraulic pressure station:

(1) Oil circuit system pressure:15Mpa<25Mpa;

(2) Hydraulic pump output volume:4L/min

(3) Motor rated power: 1.5 kw, Rated Speed:1420rpm

(4) Hydraulic Oil:YA-N46

(5) Accumulator nitrogen filled pressure:7Mpa - head pressure sensor device;

- Head melting temperature sensing display device

- Strand tooling plate: aluminum heater and a set of;

- Interlock system

(1). intelligent instrument, PID parameter self-regulation, heator broken circuit indication

(2). single screw extruder head is installed with indication of melt pressure and temperature. Melt pressure is interlocked with main frame, over pressure protect. - Electric controlling system

(1) 3*380v .50HZ

(2) AC contactor :SIEMENC brand

(3) Main motor air switch: LG brand

(4) Intermediate relay:OMRON brand

(5) Temperature controller:OMRON brand

(6) Other low voltage electrical and button, switch: all use the French Schneider

(7) Electric control cabinet include temperature control system and driving system - Die face water-ring hot cutting auxiliary system

(1) Water-ring hot cutting pelletizer:2.2kw, one set;

Adjust Speed Method: adopting "TECO" AC frequency conversion speed

(2) Hot cutting cover: Stainless steel. 1pc

(3) Water pump:one set,power: 5.5kw

(4) Diversion trench: stainless steel material,1PC

(5) Centrifugal dehydrator:one set,4kw

(6) vibrating screen:one set,

(7) dyer silo:one set,including 0.75m³silo,3kw blower,adoptφ160 soft pipe. - input oil seal:1 set

- internal Hexagon wrench:1 set

- Asbestos glove:1 pair

- hot cutting blade:10 pcs

High torque gear box,gear box shaft apply high strength alloy steel and cementite quenching treatment ,high percision and high hardness transmission stabilization 、low noise 、high efficiency

Main motorHydraulic pressure automatic screen exchanger:

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos