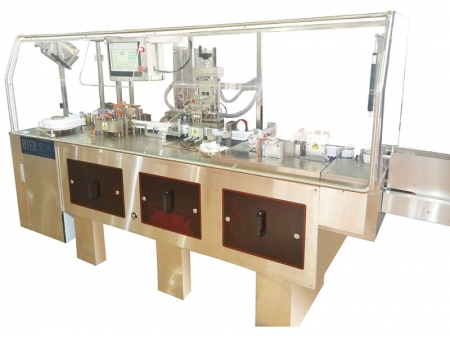

Ampoule Filling and Sealing

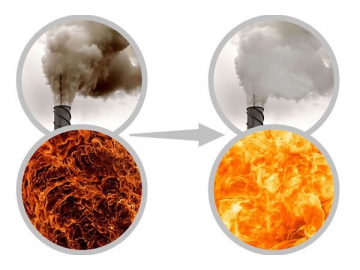

In the pharmaceutical industry where pills and liquids are bottled daily, flame sealing is an efficient and important part of the production process. The key technological condition for sealing is the flame. Mass production using oxy-hydrogen fuel shows that it significantly increases the drawing-sealing qualification rate compared with common fuel gas.

With clean energy technology such as oxy-hydrogen, your pharmaceutical bottles won't leak air and will have a smooth seal without scorches, deformities, or twists. The ampoule drawing-sealing machine using an oxy-hydrogen generator has the advantages of a non-toxic flame and is free from contamination, burned particles, and corrosion.

Traditional fuel gas (petrol atomization gas, acetylene gas, coal gas, liquefied petroleum gas, or natural gas) will produce solid particles after burning, which may come in contact with or contaminate the drugs in the bottle. Fuel gas, which adds in oxygen, brings pressure changes and impurities, which makes the flame unsteady and inconsistent in its sealing effectiveness.

Advantages of Using Oxy-Hydrogen Machines in Liquid Injection Drug Sealing (Ampoule Filling and Drawing-Sealing) Clean and Environmentally-Friendly

After combustion, the oxy-hydrogen returns to the form of water, clean, odorless, and free from any toxic substances or beginning compositions. The oxy-hydrogen equipment doesn't contaminate people, the environment or the product with harmful COx, SOx generated by common fuel gases, and it satisfies GMP requirements on ampoule filling and drawing-sealing.

Efficient

The high energy gas is made for immediate use so there's no need for storage or transportation costs. The qualified sealing rate is more than 98%, and the sealing is strong and tight. It minimizes undesirable air in ampoules and increases production efficiency.

Professional

Multiple safety protections are around the sealing flame plate and flame nozzle to ensure the user's safety and create a steady flame and stable sealing quality.

Economical

Because the fuel is made from water and electricity, the expenses of storing and transporting gas are eliminated. The initial investment in the equipment can be earned back within one year.

Safe

Because the gas is freshly produced for immediate use, no gas is stored inside the equipment, eliminating potential safety hazards. The oxy-hydrogen outlet has a water safety seal to prevent damages done by burn-back.

Convenient

Our oxy-hydrogen generator is small and light, so it is portable and space-saving. The oxy-hydrogen is conveyed by only one pipe, which has a clean inner surface according to GMP requirements. It is easy to operate with a simple on/off button.