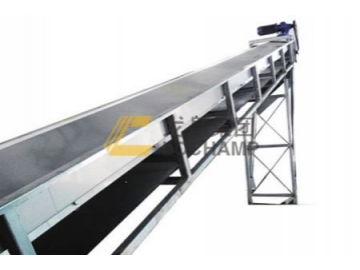

Inverter Drive to Achieve Power Balance on Belt Conveyor

The AC60 series inverter drive has the following advantages in applications on belt conveyor:

1. Truly realize the soft start of belt conveyor systems.

By the use of soft-start function of the inverter, the soft start of motor and the soft start of belt conveyor are integrated. The motor starts slowly and drives the belt conveyor to move slowly. The energy stored inside the belt is also released slowly, so the tensile waves formed during the start are small enough not to cause damages to the belt.

2. Achieve power balance in multi-motor driving.

Generally, when applied to the belt conveyor, the inverter drive adopts a drag control. When multiple motors are driving at the same time, the master-slave control is used to achieve power balance. For example, a main belt conveyor of a coal mine in Henan, uses a 2 × 135KW motor drive. By using the master-slave control, the difference between master and slave currents at light load is about 5A, and the difference is about 2A at full load. So the power balance in multi-motor driving is achieved.

3. Less demanding for high belt strength.

Because the starting time of the inverter is adjustable within 1s ~ 6500s, usually, the starting time of belt conveyor can be set within 60s ~ 200s. With extended starting time, the belt will not have to be with very high strength, which means that the initial investment in the equipment will be reduced.

4. Low maintenance.

The frequency inverter is an integration of electronic components. It converts the mechanical life into the electrical life, and the long life greatly reduces equipment maintenance. Meanwhile, by the use of the soft start function of the inverter, the starting process almost has no impact on the machine, and greatly reduces the maintenance workload of mechanical part of the belt conveyor system. For example, a coal mine in Henan saves ten thousand yuan on the belt buckle only, after equipping the belt conveyor with inverter drive.

5. Smooth start, large torque, no stroke current, enabled heavy load start.

6. Energy conservation.

After the belt conveyor uses the frequency inverter, the energy saving effect is mainly shown in the power factor and the efficiency of the system.