Centrifugal Spray Dryer

- Rotary atomizer

- Air broom system

- Large scale spray dryer (on site)

- Large scale spray dryer (on site)

The pressure atomizer spray drying machine will compress the feeding material into the nozzle atomizer on top of the drying tower, so that the material will be atomized into tiny fog-drops. They will fall down from the top of the tower along with hot air so that it can be dried. Thus, the slurry with higher solid content can be atomized and granulated by pressure. Then it will be dried to form spherical particles. The dried product features good free fluidity.

The centrifugal spray dryer has three kinds of structural layout:

- Conventional Spray Dryer

- Versatile Spray Dryer, Single Point Discharge

- Versatile Spray Dryer, Two Point Discharge

The atomizer of this centrifugal spray dryer adopts SKF bearing imported from Sweden. The unloaded vibration value of this kind of bearing is smaller than 5um. And the loaded vibration is less than 15um. The whole dryer can run up to 7000h without failures. It can also be equipped with additional vibration system which can be used to clean the powder on the inner wall of the dryer via vibration. The powder can also be cleaned by air sweeper.

The following are some kinds of commonly used centrifugal spray dryer for you to choose from, you can also make some related improvements on the base of various types:| Type Item | LPG -5 | LPG -25 | LPG -50 | LPG -100 | LPG -150 | LPG -200 | LPG -500 | LPG -800 | LPG -1000 | LPG -2000 | LPG -3000 | LPG -4500 | LPG -6500 | |

| Water evaporation(kg/h) | 5 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 2000 | 3000 | 4500 | 6500 | |

| Spray type | High speed rotary atomizer | |||||||||||||

| Atomizer speed(r/min) | 25000 | 18000 | 16000 | 12000-13000 | 11000-12000 | |||||||||

| Atomizing diameter (mm) | 50 | 102 | 108 | 180-210 | Decided according to process requirements | |||||||||

| Tower diameter(m) | D | 0.9 | 1.75 | 2.3 | 2.7 | 3 | 3.2 | 4.7 | 5.6 | 6.2 | Decided according to process flow, factory condition and user requirements | |||

| Floor area length (m) | M | 1.6 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | ||||

| Floor area width (m) | L | 0.91 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 | ||||

| Tower height (m) | H | 1.75 | 4.5 | 5.5 | 6.7 | 7.2 | 8 | 10 | 11 | 15 | ||||

| Nozzle hoisting height (m) | H1 | - | 2.5 | 2.5 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 | ||||

| Note: the water evaporation quantity is related with material features, solid content and hot air inlet and outlet temperature. | ||||||||||||||

Atomizer:cooling device on top of the tower which can be used to reduce the inner wall temperature of the tower.

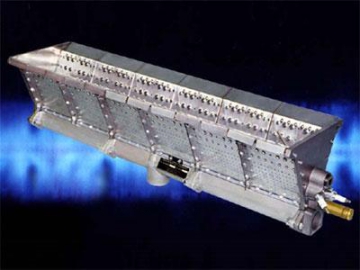

Direct-fired combustor control assembly

Direct-fired combustor control assembly Direct-fired combustor nozzle

Direct-fired combustor nozzle Pneumatic conveyor

Pneumatic conveyor

If you have interest on our centrifugal spray dryer, please contact us. If there is no drying machine which can satisfy your requirements, please tell us your demands, and we will provide related solutions according to your requirements.