Engine Components and Parts

Induction Hardening Machine for Engine Components and Parts

Engine parts that typically require induction heat treatment are camshaft, crankshaft, and valve. The processing of crankshaft is the most difficult, mainly because of the uneven quality distribution on inner side and outer side of the crank. Using the same heating power will inevitably lead to the temperature difference between sides, and consequently the emergence of cracks at fillets.

Due to the presence of eccentricity, camshaft heating will encounter similar problems. As for the valve, the heating quality is key to the automatic mass production, including automatic loading and unloading, as well as process monitoring. On these issues, we have very sophisticated engineering technology to solve problems in these parts quenching process. We offer a variety of induction heat treatment solutions. To know more, welcome to contact us.

Large crankshaft

Due to structural characteristics, namely the existence of eccentricity and crank portion, the large crankshaft cannot be easily quenched. Our automatic duplex crankshaft hardening production line is specially designed to solve the problem. It adopts diversion power adaptation technology and load servo technology, to ensure stable production and consistent quality. The equipment is fully automatic, suitable for surface hardening of varieties of automotive parts in large quantities.

Configuration and parameters

Station 1: simultaneous hardening by four inductors

Station 2: simultaneous hardening by five inductors

Two stations work alternatively

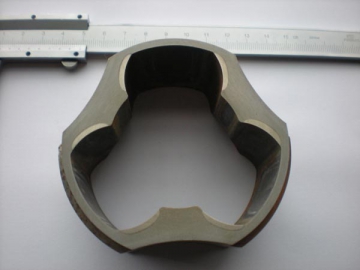

Small crankshaft

The process is similar to that of large crankshaft. Eccentric fixtures can be used in the quenching of small rod neck, and the application of diversion power adaptation technology facilitates the quenching of rod neck, fillet and spindle neck. These three parts can be quenched simultaneously by the two stations.

Configuration and parameters

Machine tool: HKVP500/2, HKVP500, one unit each

Power supply: HKTP100kW/30kHz, two units

Camshaft

The camshafts are very typical parts in heat treatment. Conventional heat treatment It is difficult to achieve a uniform hardened layer (i.e., what we call profiling) using conventional method. Our HKVC series of CNC vertical duplex universal quenching machine uses ordinary round ring inductor but special process to achieve the profiling of the hardened layer. It reduces production costs and improves productivity. This hardening machine is suitable for a variety of shafts, disks and other parts. The processing method is piecewise continuous quenching.

Configuration and parameters

Number of stations: 2

Move: workpiece moves

Quenching length: 10-500mm

Quenching diameter: Ф10-Ф100mm

Workpiece speed: 30-120rpm, continuously adjustable

Repeat positioning accuracy: ± 0.1mm

Maximum workpiece weight: 10kg

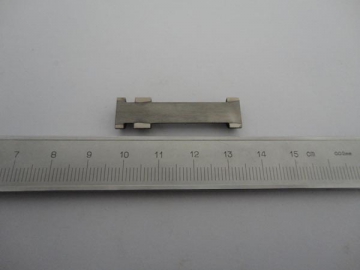

Alternator shaft

Alternator shaft parts are too tiny to be easily hardened. So we specially developed the fully automatic micro shaft induction hardening line for the quenching of small diameter shafts. In 16 years, we have accumulated a great deal of heat treatment expertise and experience. The process allows us to meet customer demands for micro motor shaft hardening. The machine is fitted with the process parameter monitoring system.

Configuration and parameters

Power supply: HKSP80kW/400kHz

Workpiece length: 60mm-200mm

Workpiece diameter: Φ6mm-Φ20mm

Workpiece hardened layer depth: 0.6-1 .5 mm

Typical parts: micro motor shaft

Water pump shaft

The water pump shaft is important parts in automotive engine cooling pump. In order to improve the strength, toughness and fatigue life of the water pump shaft, we developed HKHP200/2 double station horizontal CNC quenching machine. The machine is suitable for performing continuous scan hardening on all kinds of water water pump shaft and shaft parts. It uses Siemens CNC system to control inductor and workpiece positioning and scanning. With PLC connection to medium- and high-frequency power supply, the machine achieves automatic hardening of various workpieces.

Applicable parts

Workpiece length: 50mm-10000mm

Workpiece diameter: Ф10mm-Ф800mm

Maximum workpiece weight: 10000kg

Workpiece/inductor maximum speed: 500mm/s

Maximum workpiece length: 200mm