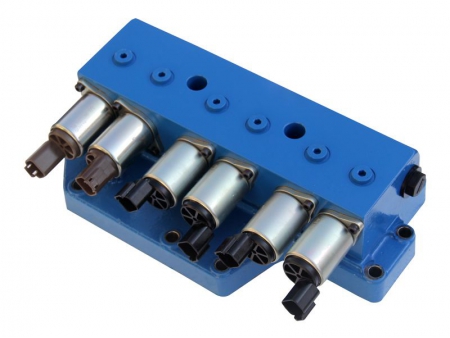

Gearbox System

Induction Hardening Machine for Gearbox System

The input, output shaft and ball stud of gearbox are parts that need induction heat treatment. Because the input and output shaft have splines or keyways, it is very challenging to perform induction treatment on them. While the ball stud, due to the rotational friction operating state, requires higher hardness to improve wear resistance.

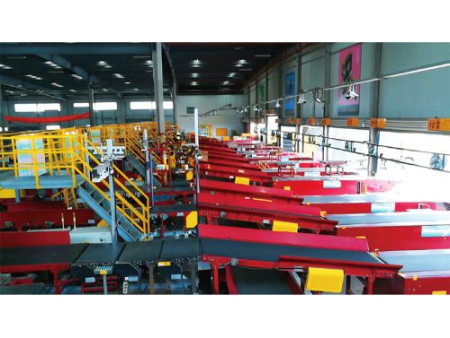

Specially, we have developed solutions to this problem. Our HKVC500/4 four-station rotary automatic CNC quenching machine is specialized in hardening gearbox parts. According to the structural characteristics and processing requirements of the parts, we carried out systematic analysis and test production. In this way, we determined the feasibility of heat treatment and quenching process specifications to facilitate mass production.

Configuration and Parameters

1. Number of stations: 4 (1 quenching station, 2 auxiliary cooling stations, 1 loading and unloading station)

2. Inductor moving speed: 40-200 mm/s

3. Workpiece speed: 20-150rpm, adjustable

4. Maximum turning diameter: Φ500mm

5. Maximum processable diameter: 420mm

6. Maximum quenching diameter: Φ150mm

7. Repeat positioning accuracy: ± 0.05mm.

8. Maximum load per station: 10kg

9. Processing speed: ≤15 seconds / pc