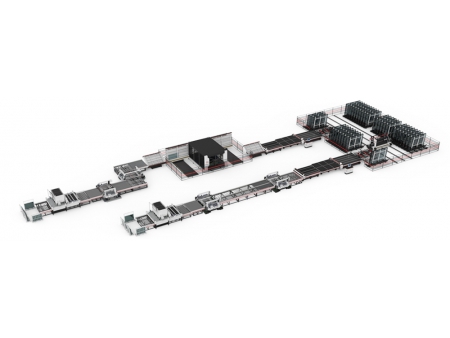

Turnkey Biodiesel Plant

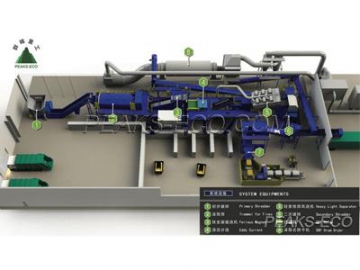

I. Factory Construction

Building a 20t/d biodiesel production facility from ground up seems to be a daunting task for many who are new to the used oil recycling business. Instead of stressing yourself out, let Yilong help you. Our factory designers carefully divide your biodiesel processing factory into 6 major sections, each for feedstock storage, esterification, vacuum distillation, biodiesel product storage, heat supply, and officing.

The entire factory covers an estimated 3500-square-meter land area, 3000m2 of which is dedicated to production while the remaining 500 m2 is used as an office. The factory is to be built in a garden-like setting, with excellent landscaping of course. The production zone will have all the facility needed for operation, all the while leaving room for future production scale-up.

1. Feedstock Storage

The feedstock storage zone, covering a land area of 1000 square meters, is supposed to accommodate a 600m3 dry bulk storage silo while still allowing for 400 m3 expansion.

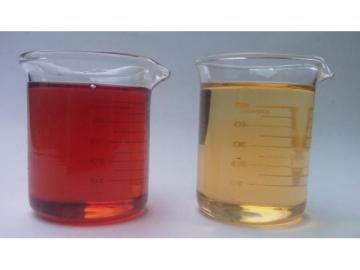

2. Esterification and Distillation

(1) The esterification workshop is 20m by 10m by 10m in dimension, with an estimated daily yield of 100 tons.

(2) Next to the esterification workshop is a 10×10×15 facility dedicated to oil distillation. The reason why we put the two workshops close together is to reduce time and money spent on material transfer between adjacent processes.

3. Biodiesel Storage

This storage zone is where biodiesel product is filled into barrels for storage, spanning a land area of 1000 square meters.

4. Heat Supply

The heat supply workshop provides a constants supply of heat to all processes needing power. Inside the workshop are coal-fired boilers, thermal oil heaters, and a reservoir. Coals and coal ashes are stored in separate places. The entire heat supply system covers a land area of around 200 square meters. Dimension: 5×10×3m

5. Back-up Equipment

This warehouse, 5×5×3m in dimension, is mainly used to put back-up equipment for production.

6. Used Barrels

Stores used barrels temporarily on a 100-square-meter site.

7. Landscaping

II. Workforce

1. Production Workers

Loaders : 4 (Loaders use loading equipment.)

Operators : 6(3 for esterification and 3 for distillation)

Lab worker : 1

Repair men : 2

Electricians : 2

Technician : 1

Boiler workers : 2

Trainers : 2

Technicians give overall training to all staff in the factory. Workers in each position need to improve themselves in their day-to-day operation.

Production Capacity

A typically day of operation produces 20 tons of biodiesel, though the maximum production rate is 100 tons per day.

Biodiesel 20 tons/day

Vegetable oil derived bitumen 2 tons/day

This turnkey biodiesel project is expected to take 3 months to complete. Machine commissioning and operator training take another 1 month.

Investments

1. Land

Land price or rent varies from region to region, country to country.

2. Factory

Building a new factory needs money ranging from hundreds of thousands to millions RMB.

3. Equipment

A 20t/d biodiesel processing system requires 2 million RMB, including the biodiesel processor, heat supply, and power supply.