Solutions for Washer Problems

Problem 1

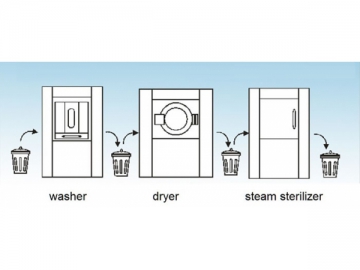

Recently in many pharmaceutical enterprises and food industry, the asepsis clothes are cleaned through three different equipment in order, washer, dryer and steam sterilizer. In this way, the energy is badly consumed, the space is seriously occupied and the human resources will be wasted. It is most likely to cause cross contamination that fails to meet GMP and FDA standards.

Solution 1

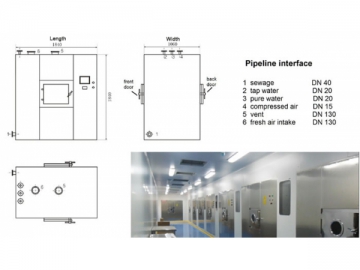

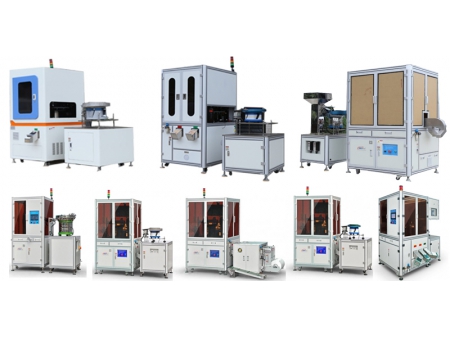

In order to adapt to the new requirements for laundry equipment from modern pharmaceutical enterprises, our company has developed ZMXY series Sterilization Twin-door Barrier Washer that combines cleaning, drying and sterilizing together. It has granted to the patent.

The advantages of this washer are as follow:

Larger capacity of washing

Shorter processing cycle

Less electrical power, air, water, and human resources

High degree of automation

No cross contamination

Meet the FDA standards and new version GMP standards

Problem 2

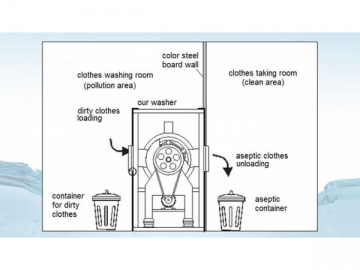

The ordinary industrial washers that are used by most of pharmaceutical enterprises are single-door type, not suitable for aseptic isolation between clothes washing room (pollution area) and clothes taking room (aseptic area). If the washed clothes are taken out from the same clothes washing room, they are likely to be contaminated again. The FDA and GMP standard.

Solution 2

Our company has developed ZMXY series sterilization Twin- door Barrier Washers and JFXY series Twin-door Barrier Washers. The design of twin-door for those two series of washers is perfect for the aseptic isolation between pollution area and clean area, which avoids the second contamination and meet the FDA standards and new version GMP.

- Double door design

- separate area

Problem 3

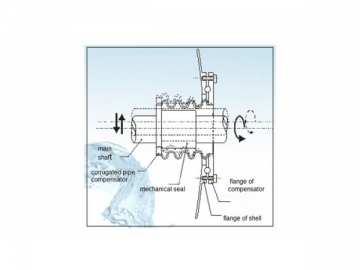

When the washers are dehydrating, the whole machine will vibrate violently. It will cause the failure of the soft seal between the outside surface of washers and isolation wall (color steel board wall), and the strict seal and aseptic isolation between pollution area and clean area cannot be guaranteed.

Solution 3

In order to achieve the rigid seal between the outside surface of washers and color steel board isolation wall, we adopted the unique floating anti-vibration system in the washers to prevent the violent shaking of the whole machine.

Shock absorption structure

Shock absorption structureProblem 4

The outer surface of drum and the inner surface of shell in the ordinary industrial washers that are used by most of pharmaceutical enterprises cannot be washed. After running for some time, there will be a layer of black gunk on the outer surface of drum and the inner surface of shell, and this black gunk shall be a source of serious second pollution to the aseptic clothes. The normal industrial washers should be disassembled while cleaning the outer surface of drum. Then it is impossible to guarantee the clean degree of clothes.

Solution 4

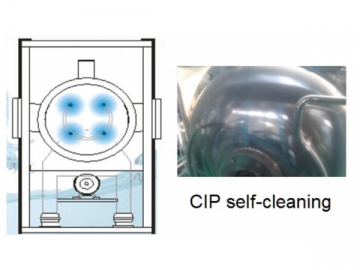

There are several universal spray balls in each of our ZMXY series Sterilization Twin-door Barrier Washers and JFXY series Twin-door Barrier Washers. Those eight universal spray balls can wash the outer surface of drum and inner surface of shell in the same time of clothes washing. It is called CIP online self-cleaning function. Meanwhile, the design of our drum is for easy manual cleaning. All of these ensure the washers in pharmaceutical enterprises meet the requirements of FDA and new version GMP.

CIP self cleaning

CIP self cleaningProblem 5

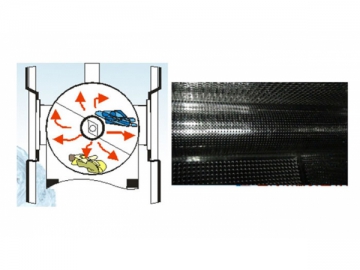

As shown in the photo, the drum of the ordinary industrial washers that are used by most of pharmaceutical enterprises is single-cavity type, and it has disadvantages as the following:

1. The cleaning method of single-cavity drum is friction type cleaning, which is easy to break the fiber of clothes. The service life of clothes will be short.

2. It does not allow many clothes to load.

3. The washers have violent vibration and loud noise as a result of imbalance of weight in the drum when the washers are dehydrating. The mechanical life of washer will be short.

4. The clothes are easy to wind and the cleaning effect is poor.

Single-cavity drum

Single-cavity drum Separate-cavity drum

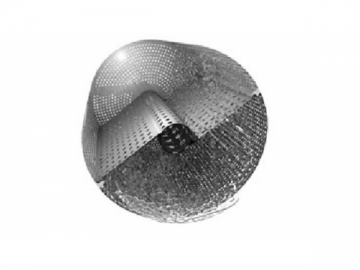

Separate-cavity drum As shown in the photo, the drum of our products ZMXY series Sterilization Twin-door Barrier Washers and JFXY series Twin-door Barrier Washers is double-cavity type, there are two compartments in the interior of drum. It has advantages as the following:

1. In positive-negative reverse program, the cleaning method of double-cavity drum is mechanical beating cleaning type, not friction cleaning type. The fiber of clothes will not be broken and the service life of clothes will be much longer.

2. The double-cavity drum allows more clothes to load. There will be a balance of weight in two cavities. No vibration and noise when the washer is dehydrating. The machine working life will be longer.

3. The clothes can hardly wind in the double cavity drum, which makes it beneficial to wash and dry.

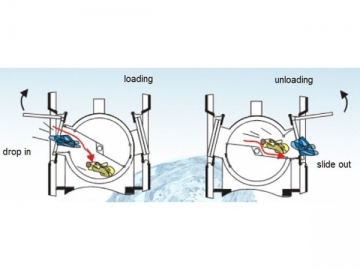

4. The double-cavity drum has another good effect: the clothes will drop in when loading (easy to load) and the clothes will slide out when unloading (easy to unload).

Separate cavity loading and unloading

Separate cavity loading and unloadingProblem 6

The method of drying clothes is sending the hot air from outside into drum by a blower. However, in common industrial washers, the air is heated by traditional electric pipes or wires before blowing into drum. This heating system has the disadvantages as the following:

1. After long time of running, on the surface of heating elements, there will be a layer of oxidizing material that is easy to peel off. The clothes will be polluted when the hot-air enter into the drum from the heating elements.

2. The factor of safety for this heating system is low, and the temperature control is unstable. The clothes will be damaged if the temperature is too high.

3. The service life of this kind of heating material is short, which requires frequent replacing.

Solution 6

All of our medical grade washers are equipped with PTC ceramic heating system. The advantages are as the following:

1. No oxidized material appears on the specially treated surface of ceramic heating elements after a long time of heating.

2. The factor of safety of this heating system is much higher. The temperature control is very stable. The temperature will never exceed the upper limit, and thus, the clothes will not be damaged.

3. The working life of ceramic heater is much longer without frequent replacements.

4. Due to heating characteristics of PTC ceramics, with the high efficiency of heating, the electric power can be largely saved.

5. The high efficiency filter for high-temperature air is also installed in the air inlet of machine to ensure the cleanness of air.

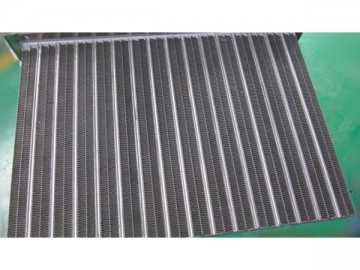

PTC ceramic heating system

PTC ceramic heating systemProblem 7

1. The method of clothes drying of ordinary industrial washers is sending the hot-air by a blower into the drum from the porous outer surface of drum. But the hot-air will be largely stopped by the surface of drum, only a small part of hot-air can get into the drum through some small holes for drying the clothes, then the drying efficiency is surely much lower. Most of the thermal energy is wasted.

2. The method of air shower and cooling for clothes in ordinary industrial washer is sending the cool-air by a blower into the drum from its porous outer surface. But the cool-air will be largely stopped by the surface of drum, only a small part of cool-air can get into the drum through some small holes, then the speed of air shower and cooling for clothes cannot be removed, which still stay in the drum. Because the broken fiber and particles are the sources of bacterial contamination. The washed clothes not only cannot reach the clean standards, but also will pollute the clean room environment.

Solution 7

All of our medical grade washers adopt the way to send the air from the center of drum. The air speed can reach to 750 cubic meters/hour. The advantages of this way are as the following:

1. The hot-air is sent out in 360°direction from the porous pipe in the center of drum. Almost 100% of the thermal energy is adsorbed by clothes. The clothes are quickly dried, the efficiency is high, and the working time and electric power are saved.

2. The cool-air is sent out in 360°direction from the porous pipe in the center of drum. The clothes will be cooled quickly. The broken fiber and particles in the clothes can be removed completely and can be sent out from the drum. The washed clothes not only reach the clean standards, but also keep the clean room environment from pollution.In this way, the purpose of air shower can be effectively achieved.

- Air enters from the center

- Center drying

- Air shower

Problem 8

The design of ordinary industrial washers is according to GB standard. They are operated with buttons. After the clothes washing, there will be no automatic records about the whole working process, and even no historical record can be traced. The certification requirements and FDA standards and new version GMP standards cannot be achieved.

Solution 8

All kinds of our washers are equipped with touch screen operation with possibility of setting own laundry process and real-time condition monitoring. The man-machine interactive performance is perfect, because the software system is designed according to the requirements of new version GMP standards and the relevant requirements of European Union. All the washing process can be recorded or printed, and the historical records can be traced. The certification requirements and FDA standard and new version GMP standards cannot be achieved.

Problem 9

In most of pharmaceutical enterprises, the washed clothes are unable to be checked on clean degree and broken fiber residues.

Solution 9

Our Helmke Drum model XL-400 is specially used to check the clean degree and broken fiber residues of clothes. It can draw the conclusion whether the relevant requirements are achieved.