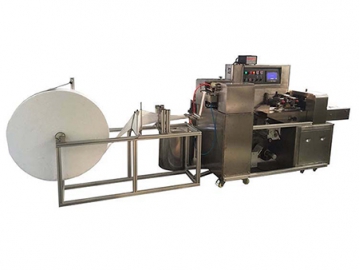

Wet Wipe Machine

Request a Quote

With improvements to quality of life and the development of the good hygiene habits around the world, wet wipes have become an indispensable part of people’s daily life. Wet wipes are easy to use and can quickly clean surfaces, removing dirt and bacteria. Wet wipes are so widely used in our lives that it is very important to guarantee their quality during production.

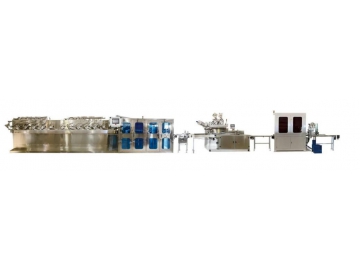

Gachn can provide complete process of pouch packing systems, which include folding, adding liquid, and packaging. Compared with traditional flexible packaging lines, our packaging line has higher production efficiency, the equipment features fine sealing ability and better quality.

Innovative designs

- We adopt a quantitative liquid adding system, replacing the traditional method (soaked liquid adding) of controlling the weight of liquid to be added using total immersion with a flow sensor. Better stability is achieved while adding liquid and prevents the product from being polluted, which can maintain the wet wipe weight error range at ±1g.

- Through an automated butt wielding system, online monitoring of the product's coil diameter, inspecting using electronic eye and increasing tension caching mechanism, we can make sure that the product butt wields automatically once the feeding of the material is done. The machine increases production efficiency by sealing materials automatically at constant speed and without going down.

- Substandard products are removed online by improving the waste detection mechanism to prevent its outflow, the accuracy of removing inferior product is 99.9%.

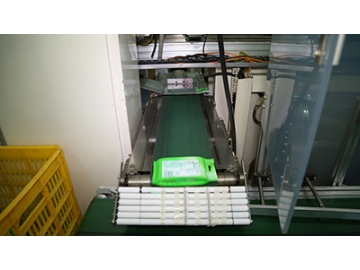

- The product is sent to enter the final steps of packaging through an automated stacking and pushing mechanism instead of using manpower.

Benefits

- The products produced by our wet wipes production line maintains the stability of quality and product weight, which can prevent unnecessary chemical waste and lower cost.

- Waste rate is reduced to less than 2%, which reduces the cost of production as the use of packaging material and non-woven material is cut down.

- The flexible packaging system has automated butt wielding unit which increases the work efficiency and reduces labor costs.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos