Self-Cleaning Piano Wire Screen

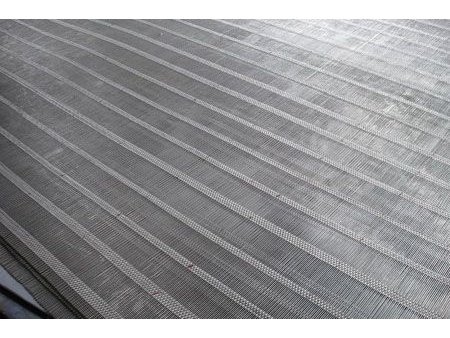

DUNPAI manufactures its piano wire screens with quality high-manganese steel and stainless steel, which ensure far fewer declines in screening capacity and efficiency over a long period.

With regard to service life, our self-cleaning wire screens have thick wires and the screen surface features uniform tensions, which avoid damages to screens and ensure a long service life.

Our piano wire screens can be applied in mining industry to solve screens clogging problems, since they have no cross wires, which ensure maximum Opening Areas, allowing for the effective screening of sands, pebbles, soils, topsoil and fertilizers. The opening of our wire screens ranges from 1/16 inch – 1 inch.

Features- Anti-clogging and anti-pegging;

- Fine screening;

- Quality materials;

- Increased service life

| Aperture Width (mm) | Wire Diameter(mm) | Wire Diameter (inch) | Weight/m2 | Open Area | Material |

| Linked by polyurethane | |||||

| 2.00 | 0.8 - 1 | 3/64” - 1/16” | 2,8 - 4,4 | 62 - 56 | AR/AISI 304/AISI 316 |

| 2.50 | 1,20 - 1,60 | 3/64” - 1/16” | 2,4 - 3,8 | 67 - 61 | AR/AISI 304/AISI 316 |

| 3.00 | 1,20 - 2,00 | 3/64” - 5/64” | 2,2 - 4,9 | 71 - 60 | AR/AISI 304/AISI 316 |

| 3.50 | 1,20 - 2,00 | 3/64” - 5/64” | 1,9 - 4,5 | 74 - 64 | AR/AISI 304/AISI 316 |

| 4.00 | 1,20 - 2,00 | 3/64” - 5/64” | 1,8 - 4,1 | 77 - 67 | AR/AISI 304/AISI 316 |

| 4.50 | 1,20 - 2,00 | 3/64” - 5/64” | 1,6 - 3,8 | 79 - 69 | AR/AISI 304/AISI 316 |

| 5.00 | 1,20 - 2,80 | 3/64” - 7/64” | 1,5 - 6,2 | 81 - 64 | AR/AISI 304/AISI 316 |

| 5.50 | 1,20 - 2,00 | 3/64” - 5/64” | 1,4 - 3,4 | 82 - 73 | AR/AISI 304/AISI 316 |

| 6.00 | 1,20 - 3,15 | 3/64” - 1/8” | 1,3 - 6,7 | 83 - 66 | AR/AISI 304/AISI 316 |

| 6.30 | 1,20 - 2,00 | 3/64” - 5/64” | 1,2 - 3,1 | 84 - 76 | AR/AISI 304/AISI 316 |

| 7.00 | 1,50 - 3,15 | 0,059 -1/8” | 1,7 - 6,0 | 82 - 69 | AR/AISI 304/AISI 316 |

| 7.50 | 2,00 - 2,50 | 5/64” - 0,098 | 2,6 - 3,9 | 79 - 75 | AR/AISI 304/AISI 316 |

| 8.00 | 1,50 - 3,15 | 0,059 -1/8” | 1,5 - 5,5 | 84 - 72 | AR/AISI 304/AISI 316 |

| 8.50 | 2.50 | 0.098 | 3.60 | 77 | AR/AISI 304/AISI 316 |

| 9.00 | 1,50 - 3,15 | 0,059 -1/8” | 1,4 - 5,0 | 86 - 74 | AR/AISI 304/AISI 316 |

| 10.00 | 1,50 - 4,00 | 0,059 -5/32” | 1,2 - 7,2 | 87 - 71 | AR/AISI 304/AISI 316 |

| 10.50 | 2,50 - 3,15 | 0,098 -1/8” | 5,0 - 7,7 | 66 - 60 | AR/AISI 304/AISI 316 |

| 11.00 | 3,15 - 4 | 1/8” - 5/32” | 4,3 - 6,7 | 78 - 73 | AR/AISI 304/AISI 316 |

| 11.50 | 4.00 | 5/32” | 6.5 | 74.0 | AR/AISI 304/AISI 316 |

| 12.00 | 1,50 - 4,00 | 0,059 -5/32” | 1,1 - 6,3 | 89 - 75 | AR/AISI 304/AISI 316 |

| 13.00 | 3,00 - 4,00 | 0,118 -5/32” | 3,6 - 5,9 | 81 - 76 | AR/AISI 304/AISI 316 |

| 13.50 | 2.80 | 7/64” | 5.4 | 68.0 | AR/AISI 304/AISI 316 |

| 14.00 | 2,00 - 4,00 | 5/64” -5/32” | 1,6 - 5,5 | 87 - 78 | AR/AISI 304/AISI 316 |

| 15.00 | 1,60 - 4,00 | 1/16” -5/32” | 1,0 - 5,3 | 90 - 79 | AR/AISI 304/AISI 316 |

| 15.50 | 3,00 - 3,15 | 0,118 -1/8” | 5,6 - 5,9 | 70 - 69 | AR/AISI 304/AISI 316 |

| 16.00 | 2,00 - 4,00 | 5/64” -5/32” | 1,4 - 5,1 | 89 - 80 | AR/AISI 304/AISI 316 |

| 18.00 | 2,50 - 4,00 | 0,098 -5/32” | 1,9 - 4,5 | 88 - 82 | AR/AISI 304/AISI 316 |

| 20.00 | 1,60 - 5,00 | 1/16” - 13/64” | 0,8 - 6,2 | 93 - 80 | AR/AISI 304/AISI 316 |

| 22.00 | 4.00 | 5/32” | 3.80 | 85 | AR/AISI 304/AISI 316 |

| 25.00 | 3,00 - 6,30 | 0,118 - 1/4” | 2,1 - 7,8 | 89 - 80 | AR/AISI 304/AISI 316 |

| 28.00 | 6.00 | 0.236 | 6.60 | 82 | AR/AISI 304/AISI 316 |

| 45.00 | 5.00 | 13/64” | 3.10 | 90 | AR/AISI 304/AISI 316 |

Harp Type self-cleaning piano wire screens are a specially designed screen type commonly used in industrial screening processes. They offer good screening efficiency and wear resistance, finding wide application in various industries, including mining, construction materials, and chemicals.

- Ore and mineral screening: Ore, aggregates, crushed stone, coal, mineral sands, etc.

- Building and construction material screening: Cement, sand, lime, gravel, concrete, etc.

- Chemical and plastic pellet screening: Chemical powders, plastic pellets, fertilizers, coatings, etc.

- Food and agricultural material screening: Grains, coffee beans, flour, sugar, spices, etc.

- Waste recycling and environmental protection: Waste, plastic recycling, garbage treatment, etc.

- Oil and gas industry: Oil, natural gas, sand, drilling mud, etc.

- AISI 304L / EN 1.4307: Austenitic stainless steel with low carbon content.

- AISI 304 / EN 1.4301: High resistance austenitic stainless steel.

- AISI 316 / EN 1.4401: Austenitic stainless steel with molybdenum to strengthen corrosion resistance.

- AR / EN 10270: Wear resistant steel with a high content of carbon and manganese.

- NUBA Screening Media, at the customer’s request can provide a Quality Inspection Certificate (compliant with EN 10204.3.1.B) showing the chemical and mechanical properties of the materials. Other aperture/wire combinations and materials such as galvanized steel etc. are available at customer’s request.

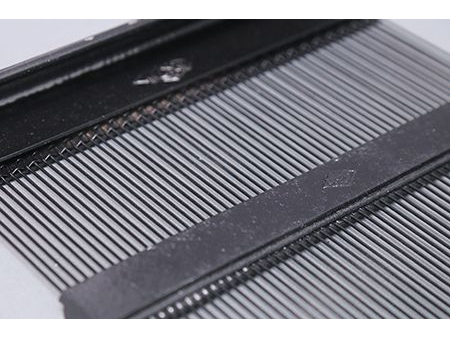

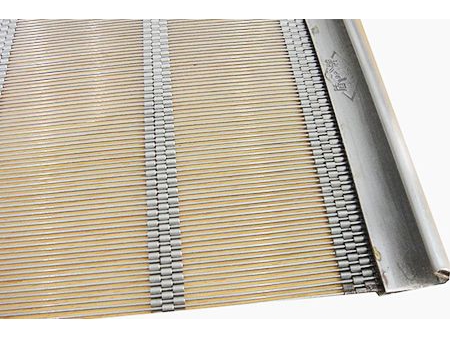

Self-cleaning screen hook strip styles