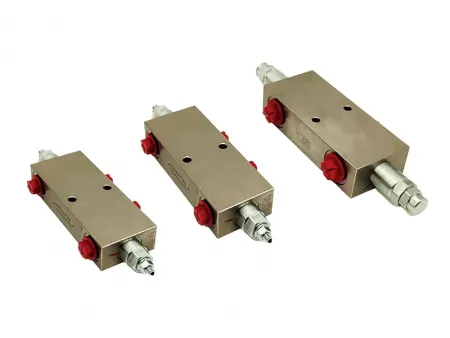

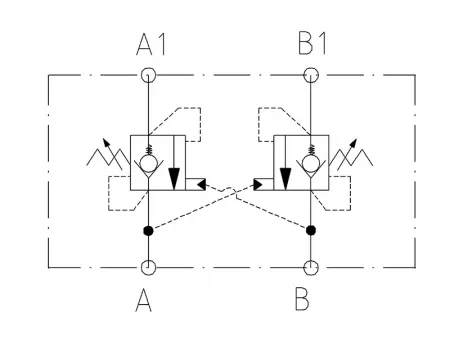

MCBS Dual Counterbalance Valve

Request a Quote

- Modular design with a compact structure, delivering safe and reliable operation

- Minimizes hydraulic shock during opening and closing, ensuring consistent pressure control

- Flexible installation to accommodate a wide range of machinery and system configurations

Model Options

| Model | Pressure | Flow |

| MCBS-08 Dual Counterbalance Valve | 350bar | 40L/min |

| MCBS-10 Dual Counterbalance Valve | 350bar | 70L/min |

| MCBS-12 Dual Counterbalance Valve | 350bar | 110L/min |

Specifications

| Rated Pressure | 350bar |

| Rated Flow | 40L/min 70L/min 110L/min |

| Fluid Temperature Range | -30℃~100℃ |

| Ambient Temperature Range | -20℃~80℃ |

| Valve Body Material | High strength cast iron (optional: aluminum alloy, carbon steel) |

| Oil Viscosity Range | ISO 20~400mm²/s |

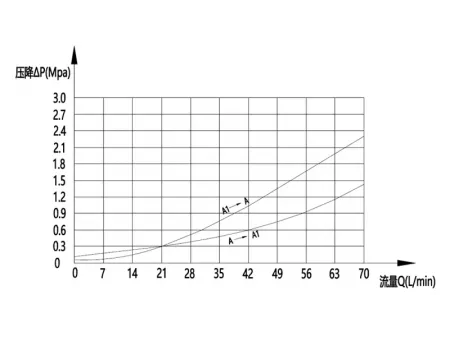

Performance Curve

MCBS-10 Dual Counterbalance Valve

MCBS-12 Dual Counterbalance Valve

Installation Dimension Drawings

MCBS-08 Dual Counterbalance Valve with Flange

MCBS-08 Dual Counterbalance Valve with Pipe Thread

MCBS-10 Dual Counterbalance Valve with Flange

MCBS-10 Dual Counterbalance Valve with Flange

MCBS-12 Dual Counterbalance Valve with Flange

MCBS-12 Dual Counterbalance Valve with Flange

Applications

Our double counterbalance valve, built to manage heavy loads smoothly, preventing them from running ahead of the pump for safer, steadier operation, is widely used in:

- Graders: Provides precise control of blade lifting and lowering, delivering stable and efficient grading performance.

- Telehandlers: Ensures balanced and controlled movement of stabilizer legs and telescopic booms, enhancing operational safety during heavy load handling.

- Aerial work platforms: Reduces unwanted oscillation during boom extension, retraction, or rotation, maintaining safe and steady high-altitude operations.

- Boom pump trucks: Enables smooth bidirectional boom movement during pumping tasks, preventing sudden or uncontrolled hydraulic actions.