Mini UV Laser Marking Machine

- Laser wavelength 355nm

- Marking range ≤200×200mm

- Beam quality M²<1.2~1.5

- Max. line speed 7000mm/s

The mini UV laser marking machine redefines small-space operation standards with its ultra-compact design and industrial-grade performance. The machine body adopts an integrated structure, combining the laser source, galvo scanner, and control system into one unit. Weighing only 62kg and occupying less than 0.5m², it is perfectly suited for space-sensitive environments such as laboratories and micro-workshops. It supports 24-hour continuous operation, significantly reducing deployment costs.

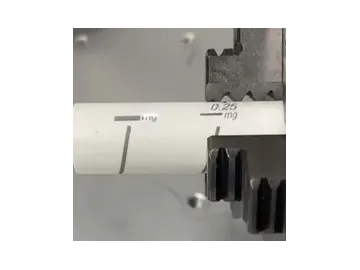

UV laser marking machines leverage cold processing, high precision, and multi-material adaptability as core competencies, excelling particularly in handling heat-sensitive, highly reflective, or materials requiring ultra-fine processing. They can achieve sub-micron level non-thermal damage engraving on surfaces including metal coatings, polymers: (e.g., ABS, PVC, HDPE, and other plastics), glass, ceramics and more.

- Plastic tube laser marking

- Leather laser engraving

- Aluminum laser engraving

- PCB laser marking

- PU hose laser marking

- Silicone hot water bag laser marking

- Glass bottle laser marking

- PC card laser marking

- Silicone cup sleeve laser marking

- Plastic animal ear tag laser marking

- Plastic bottle cap laser marking

- Glass wine bottle laser marking

- Glass goblet laser marking

- Crystal laser marking

- Technical Data

- Configuration

- Laser power 3W, 5W, 10W

- Laser type UV laser

- Laser wavelength 355nm

- Marking range ≤200×200mm

- Beam quality M²<1.2~1.5

- Max. line speed 7000mm/s

- Min. character size 0.05mm

- Min. line width 0.01mm

- Cooling method water cooling

- Power supply 220V/50Hz, 110V/60Hz

- Operating temperature 10℃~35℃ (Operating outside this range may affect equipment performance and lifespan)

- Machine dimensions 320×550×670mm (chiller 290×540×470mm)

- Package size 920×500×740mm

- Machine weight 62kg

- Package weight 72kg

Laser source

We provide renowned domestic and international brand laser sources for our equipment, such as DXT, GL, and Optowave. These sources offer high pump conversion efficiency, low power consumption, and excellent beam quality. Utilizing third-order intracavity frequency doubling technology, the wavelength is shorter than that of fiber (1064nm) and CO₂ (10.64μm) lasers, resulting in higher photon energy. This allows for direct breaking of material molecular chains rather than heating, achieving a "photo-etching" effect with a minimal heat-affected zone (<1μm), thereby preventing material deformation or scorching.

Galvo scanner

Features a high scanning speed of 7000mm/s, high stability, and is equipped with a dual-red-light focusing device, which significantly enhances focusing efficiency.

F-theta lens

Equipped with a 355nm wavelength F-theta lens, primarily used for UV laser marking machines. Due to its shorter wavelength, it is suitable for marking various metal and non-metal materials. It supports long-term operation without the need for consumables to be added or replaced. Currently, we have received no user feedback regarding F-theta lens damage.

Control card

Equipped with a genuine JCZ EZCAD control board, ensuring the stability of the entire marking system. The software interface supports multiple language versions (Chinese, English, Italian, Russian, Korean, Japanese, Spanish, Portuguese, etc.). Its powerful functions include text marking, QR code marking, vector graphic marking, automatic serial number skipping, and more.

Computer

Features an industrial computer with a Windows 10 system and a 19-inch LCD display to ensure smoother operation of the entire laser equipment.

Column

Features electric lifting and lowering, adapting to marking workpieces of various heights without manual adjustment, significantly improving overall work efficiency.

Laser safety warning labels

Plays a crucial role in scenarios involving laser applications, primarily serving to alert people to potential laser hazards and ensure personnel safety.

- Fume Extractor

- F-theta lens

- Cylindrical rotary clamp fixture

- Roller rotary axis

- UV laser

- Integrated laser control cabinet

- Work panel

- Galvo scanner

- F-theta lens

- Control card

- Laser power supply

- Laptop

- Power cord

- Water chiller

- Safety goggles

- Foot pedal switch

- Aluminum test piece

- Hex key tool set

- Equipment warranty certificate

- Shipping accessories list

- Product catalog