SBH330B/450B Roll Fed Square Bottom Paper Bag Machine

The SBH series roll fed square bottom paper bag machine is designed to manufacture square bottom paper bags from paper roll in blank or printed designs. Side gluing, tube forming, tube cutting, bottom creasing, bottom gluing, bottom forming and final product out feed can all be completed within a single operation pass by this machine. It is ideal equipment for making paper bags for food, shopping bag and other commonly used paper bags. The machine use German machinery manufacturing technology and ideas, including a high speed movement of the central control system (CPU) control. The bag length can be adjusted by servo system, allowing the machine to create bags in various specifications. Different models (SBH330B/450B) can also have a twisted or flat handle unit added to the production line.

- Servo Adjustable Former, Adjust The Face Width & Gusset Size Automatically.

- Mechanical Drive

- Bottom Forming Drum With Vacuum Assist

-

Model:

SBH150 - Paper Thickness (gsm):

- 40-150

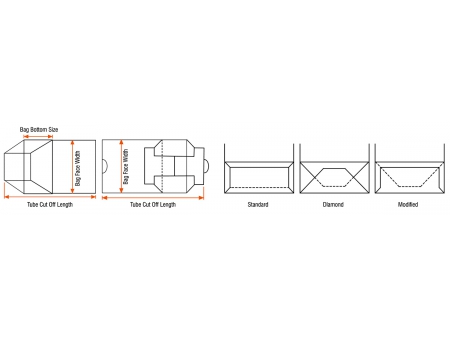

- Tube Cut Off Length (mm):

- 191-385

- Bag Face Width (mm):

- 80-200

- Bag Bottom Size (mm):

- 50-100

- Max. Speed (bags/min):

- 250

-

Model:

SBH150B - Paper Thickness (gsm):

- 40-150

- Tube Cut Off Length (mm):

- 191-430

- Bag Face Width (mm):

- 80-200

- Bag Bottom Size (mm):

- 45-100

- Max. Speed (bags/min):

- 250

-

Model:

SBH330 - Paper Thickness (gsm):

- 45-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 120-330

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 230

-

Model:

SBH330B - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 150-330

- Bag Bottom Size (mm):

- 70-180

- Max. Speed (bags/min):

- 220

-

Model:

SBH330BPro - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 150-330

- Bag Bottom Size (mm):

- 90-180

- Max. Speed (bags/min):

- 220

-

Model:

SBH450B - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 368-762

- Bag Face Width (mm):

- 200-450

- Bag Bottom Size (mm):

- 90-205

- Max. Speed (bags/min):

- 150

-

Model:

SBH450C - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 368-762

- Bag Face Width (mm):

- 200-450

- Bag Bottom Size (mm):

- 120-260

- Max. Speed (bags/min):

- 150

-

Model:

SBH550T - Paper Thickness (gsm):

- 80-150

- Tube Cut Off Length (mm):

- 360-770

- Bag Face Width (mm):

- 220-450

- Bag Bottom Size (mm):

- 80-230

- Max. Speed (bags/min):

- 150

| Technical Info | | | | | | | | |

| Paper Roll Width (mm) | 280-640 | 280-640 | 405-1050 | 465-1050 | 505-1050 | 610-1310 | 690-1310 | 630-1510 |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 |

| Paper Thickness (gsm) | 40-150 | 40-150 | 45-180 | 50-180 | 50-180 | 70-180 | 70-180 | 80-150 |

| Tube Cut Off Length (mm) | 191-385 | 191-430 | 280-540 | 280-540 | 280-540 | 368-762 | 368-762 | 360-770 |

| Bag Face Width (mm) | 80-200 | 80-200 | 120-330 | 150-330 | 150-330 | 200-450 | 200-450 | 220-540 |

| Bag Bottom Size (mm) | 50-100 | 45-100 | 70-150 | 70-180 | 90-180 | 90-205 | 120-260 | 80-230 |

| Max. Speed (bags/min) | 250 | 250 | 230 | 220 | 220 | 150 | 150 | 150 |

| Total Power (kW) | 8.75 | 8.75 | 16.5 | 18.9 | 18.9 | 17.9 | 17.9 | 23.2 |

| Machine Weight (kg) | about 5600 | about 6500 | about 8500 | about 9000 | about 9000 | about 11000 | about 11000 | about 13500 |

| Machine Size (L×W×H)(m) | 8.6×2.6×1.96 | 8.6×2.6×1.96 | 11.5×3.1×1.96 | 11.5×3.1×1.96 | 11.5×3.1×1.96 | 13×3.9×2 | 13×3.9×2 | 13×3.9×2.3 |

| Three Types Bottom Seal | yes | yes | yes | yes | yes | yes (Two) | yes (Two) | yes (One) |

| Servo Lip Cut Device | yes | yes | yes | yes | yes | no | no | no |

| M= Servo Motorized Plate Device | no | no | no | no | no | no | no | no |

| Bottom Forming Drum With Vacuum Assist | no | no | yes | yes | yes | yes | yes | yes |

| Options Unit |

| |||||||

- The roll fed square bottom paper bag machine is equipped with a Japanese Mitsubishi servo system and SICK photocell for correction, so that users can accurate track printed material, and minimize adjustment and pre-set times.

- It is equipped with a Mitsubishi electric control system and Mitsubishi motion controller (CPU). This achieves an integration of an optical fiber in order to achieve a high speed and high precision, motion control and production flow test. With a touch screen display, the operation functions are clear, and feature a great human to machine interface.

- Equipped with a tension system and automatic WEB correction system, this paper bag production machine can reduce waste and improve efficiency.

- With a servo motor adjustable forming plate, there is no need for individual formers. This also allows for a faster change between different bag sizes.

- The vacuum assisted main drum allows for better control during bag bottom formation.