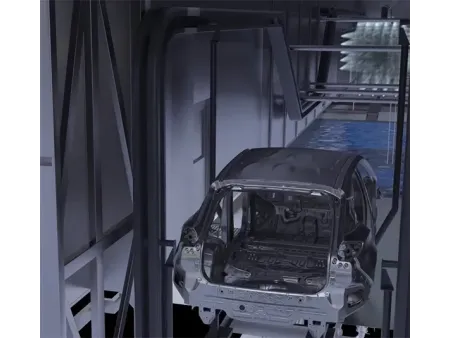

Pretreatment and E-Coating System

When your paint shop demands precision, consistency, and environmental compliance, a reliable Pretreatment and Electrophoretic Coating (E-Coating) System makes all the difference.

Tiancheng Coating, with over 30 years of expertise since its founding in 1995, designs, manufactures, and installs advanced pretreatment and E-coating systems tailored to the unique needs of manufacturers around the world. Our solutions have earned the trust of leading automotive OEMs, ensuring that every system we deliver meets strict regional standards. All our equipment complies with European CE regulations, while our electrical systems fully meet US UL certifications.

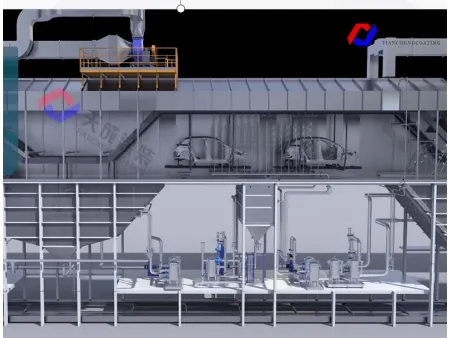

Drawing on deep knowledge of industrial pretreatment technologies, Tiancheng Coating offers flexible conveyor solutions to integrate seamlessly with your production flow. Depending on your processes and space constraints, you can choose from three proven conveyor options: pendulum conveyor system, electric monorail system (EMS) and programmable hoist conveyor system.

The pendulum conveyor system is renowned for its stable and reliable operation, easy maintenance, and excellent throughput. It’s particularly well-suited for handling workpieces with complex structures or those requiring specific hanging angles. This system remains a classic choice for transporting large, heavy, or irregularly shaped components with efficiency and precision.

The electric monorail system (EMS) stands out for its exceptional flexibility, precise positioning capabilities, and space-saving design. It’s particularly ideal for modern production lines that demand a high level of automation, complex process routes, limited space, or the need for meticulous control over workstation cycle times.

The programmable hoist conveyor system is designed with powerful lifting capacity and extensive operational coverage, making it especially suitable for handling construction machinery structures and large cast or forged parts. It’s a smart solution for saving space and reducing costs while maintaining high production efficiency and reliable performance.

- Compact Equipment Design: Ensuring optimal use of space without sacrificing functionality.

- Energy Efficiency: Lowering power consumption across all processes.

- Automation: Increasing precision, consistency, and reducing manual intervention.

- Water-Saving Technologies: Conserving water resources while maintaining high process quality.

- Optimized Conveyor Systems: Tailoring transport solutions for seamless production flow and operational efficiency.

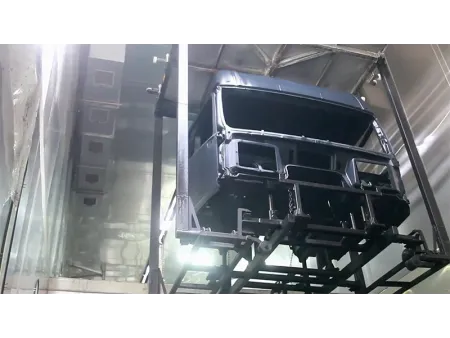

Pre-assembly in factory

Fabrication and Pre-Assembly in factory

Fabrication and Pre-Assembly in factory

The following highlights some of our recent e-coating projects

| Project Name | Capacity | Scope | Time |

| MEXICO Battery Box ED Line (with ED oven) | 13JPH | Turnkey | 2024 |

| Czech Republic Battery Box ED Line (with ED oven) | 13JPH | Turnkey | 2024 |

| USA Battery Box ED Line | 5JPH | Design, Manufacturing, Delivery | 2021 |

| USA Pendulum Conveyor System(ED Line) | 60JPH | Design, Manufacturing, Delivery | 2021 |

| Project Name | Capacity | Scope | Time |

| BYD Zhengzhou trunk frame ED Line | 13JPH | Turnkey | 2022 |

| BYD Jinan ED Line | 13JPH | Turnkey | 2022 |

| BYD Changzhou ED Line | 13JPH | Turnkey | 2022 |

| Greatwall Longyan ED pickling line | 7min/hoist | Turnkey | 2022 |

| BYD Changsha ED Line | 13JPH | Turnkey | 2022 |

| BYD Xi’an N0.50 workshop trunk frame ED Line | 13JPH | Turnkey | 2022 |

| BYD Hefei ED Line | 13JPH | Turnkey | 2022 |

| BYD Fuzhou ED Line | 13JPH | Turnkey | 2022 |

| BYD Xi’an ED Line | 13JPH | Turnkey | 2021 |

| Greatwall Shangrao ED pickling line | 7min/hosit | Turnkey | 2021 |

| Qingling Auto frame ED Line | 15JPH | Turnkey | 2021 |

| Spotlight Zhangjiagang ED Line | 7min/hoist | Turnkey | 2020 |

| FAW Jiefang J7 intelligent coating line | 15JPH | Turnkey | 2021 |

Our team is ready to help you achieve outstanding coating results with maximum efficiency and significant cost savings. We’d love to connect and explore how we can support your goals.

Our solutions cover every critical part of an automotive coating line, including Pretreatment and E-Coating Systems, Spray Booths, Oven&Coolers, ASU&ARU, and dedicated Working Decks.

What is a pretreatment and E-coating system?

A pretreatment and E-coating system is a critical combination of equipment used in coating processes, especially before electrophoretic painting. It handles essential surface treatments like cleaning, degreasing, and phosphating on workpieces such as automotive bodies and metal parts. These steps create a uniform, high-quality base layer for subsequent electrophoretic coating (E-coat). Automated processes ensure high efficiency, consistent results, and environmental compliance, making this system widely used in automotive manufacturing, metal fabrication, and similar industries.

How does your E-coating system for automotive comply with CE or UL standards?

Our E-coating rectifiers fully comply with the highest safety standards outlined in UL and CE regulations. We integrate interfaces that support IoT and Industry 4.0 connectivity, enabling maximum productivity at minimal cost. These features come as standard, not optional extras. Additionally, all our rectifiers are enclosed in robust industrial cabinets, providing extra protection and safety for your operations.

Can your cathodic electrodeposition system be integrated with an existing paint shop?

Yes, our cathodic electrodeposition (CED) systems can seamlessly integrate with your existing paint shop infrastructure and processes.

What are the energy-saving features of your cathodic electrodeposition system?

Our cathodic electrodeposition systems include multiple energy-saving technologies designed to improve efficiency and lower operational costs:

- Low-Voltage Operation: The system operates at lower voltages, significantly reducing energy consumption during the electrodeposition process.

- Heat Exchange Systems: Integrated heat recovery systems capture and reuse waste heat, reducing the energy required for heating processes.

- Smart Control Systems: Advanced automation enables precise control of process parameters, allowing real-time adjustments based on production demands and minimizing unnecessary energy use.

I want to ensure that your pretreatment system is compatible with our existing production line. Is this possible?

Absolutely. We understand the importance of compatibility in your operations. Our pretreatment systems can be fully customized and integrated with your existing production lines. Our engineering team will collaborate closely with you, conducting on-site assessments and technical evaluations to ensure seamless integration. We’re committed to providing all necessary technical support to make the transition smooth and efficient.

If the coating pretreatment system fails, it could cause production interruptions. Do you offer contingency measures and quick repair services?

We take emergency response and rapid repair services very seriously. Tiancheng Coating maintains a dedicated technical support team that responds quickly to resolve any system issues. We provide a 24-hour technical support hotline, ensuring you can reach our experts whenever needed. Additionally, we offer scheduled maintenance and service programs to help prevent failures and extend the lifespan of your equipment.

What is the CED coating process, and how is it used in the automotive industry?

The CED (cathodic electrodeposition) coating process is a method for applying protective and decorative coatings to various parts and components. It uses an electric current to deposit paint or coating materials onto conductive surfaces, resulting in a uniform, durable layer with excellent corrosion resistance.

In the automotive industry, CED coatings are widely used to protect and enhance the appearance of vehicle parts such as car bodies, chassis, suspension components, and other metal parts. CED coatings provide uniform thickness and strong adhesion, helping prevent rust, weathering, and other environmental damage. This ensures long-lasting durability and extends the service life of automotive components.

Enhance your automotive coating line applications with solutions designed for outstanding vehicle finishes and optimal paint shop performance. Rely on Tiancheng Coating for innovative systems that deliver superior quality, efficiency, and proven results.