Single Lane Window Patcher, TC-650/1100

- Normal window

- Intermittent length slitting

- Form slitting

ChangHong single lane window patcher is a fully automatic high-speed window patching machine that runs single production line at a time, offering a maximum speed of 20,000 boxes per hour. The maximum window size is 380mm in width and the 500mm in length. This window applicator is ideal for window patching on tissue boxes, cosmetic boxes, gift boxes, handicraft boxes, and other paper boxes. It can also be used for partial film patching onto cardboard and corrugated cardboard. In addition, the carton windowing machine is equipped with a mono-suction belt, which ensures continuous feeding of carton blanks. TC-650/1100 single lane window patcher is an ideal choice for manufacturers in the carton box industry, providing efficient and reliable window patching capabilities.

| Model | | |

| Max. Blank Size | 650×650mm | 650×970mm |

| Min. Blank Size | 100×80mm | 100×80mm |

| Small-Size Blank Length | 120-320mm | 120-320mm |

| Large-Size Blank Length | 300-650mm | 300-970mm |

| Max. Window Size | 380×300mn | 380×500mm |

| Min. Window Size | 40×40mm | 40×40mm |

| Power | 6.5kW | 8.5kW |

| Film Thickness | 0.03-0.25mm | 0.03-0.25mm |

| Machine Weight | 2000kg | 2500kg |

| Machine Dimensions | 5500×1600×1800mm | 5500×2200×1800m |

| Max. Speed | 20000 pcs/h | 20000 pcs/h |

Specification may be slightly adjusted for better use, without prior notice.

- 1. carton blank feeding station

- 2. aligning system

- 3. gluing station

- 4. window patching station

- 5. film feeding unit

- 6. conveying unit

- 7. delivery table

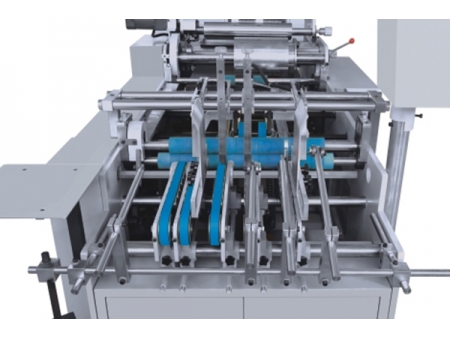

Single lane window patcher adopts a Japanese mono-suction belt for bottom feeding, allowing continuous carton blank feeding without stopping the machine. The intermittent belt conveyor is controlled by servo motors, and it has two carton blank output modes. Multiple conveying belts are equipped with gear and rack devices to adjust the positions of the belts according to the carton blank shape.

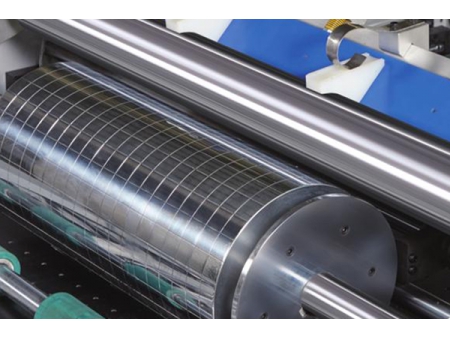

- The gluing station utilizes a 304 stainless steel gluing roller, and is equipped with a scraper device, which allows for quick adjustment of the thickness and width of the glue, while reducing waste of glue.

- Users can use flexo templates for gluing accurately and efficiently. Gluing position can be adjusted freely left and right. The front and back adjustment can be done through a phase regulator without stopping the machine.

- The gluing will lift off automatically to avoid gluing on the belt in case of no carton blank.

- The glue is dispensed automatically from an inverted container, which makes cleaning and maintenance easier.

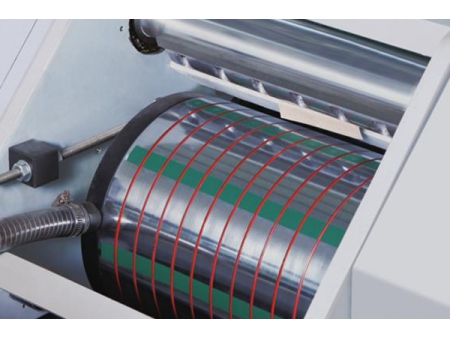

- With servo linear drive, the length of film is input through the touch screen.

- A roller knife is adopted to automatically cut the film to the desired length, press out sawtooth lines for tearing, and automatically cuts openings of the film (such as for tissue box).

- It utilizes a suction roller to apply the film onto the carton blank, allowing for free adjustment of film position without stopping the machine.

The delivery table uses a blet conveyor and stacked device to collect the patched cartons.