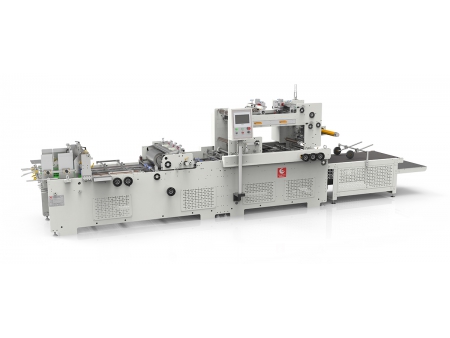

Window Patcher with Punching & Scoring Unit, CH-650/1000

ChangHong window patcher with punching & scoring unit is the latest fully automatic machine developed by ChangHong, offering high productivity and versatility. This series window patching machines has an independent window patching station, which is equipped with a double pneumatic punching and scoring unit for V cutting and creasing. This allows for creasing lines on the film via heating and heating the film for embossing with molds, filming or other processes.

The fully automatic window patching machine comes with a maximum speed of 8000 pcs/h, and the film thickness can reach 0.1-0.45mm, with a creasing accuracy of 0.5mm. The front and rear positions of the carton blank for window patching can be adjusted via touch screen or mechanical adjustment mechanisms. The film position can be adjusted by inputting parameters on the touch screen. The gluing position can also be adjusted according to the position of the film without stopping the machine, ensuring high accuracy.

| Model | | |

| Max. Blank Size | 600×650mm | 600×970mm |

| Min. Blank Size | 100×80mm | 100×80mm |

| Max. Patch Size | 300×300mn | 300×400mm |

| Min. Patch Size | 40×40mm | 40×40mm |

| Total Power | 8kW | 10kW |

| Film Thickness | 0.1-0.45mm | 0.1-0.45mm |

| Machine Weight | 3000kg | 3500kg |

| Machine Dimensions | 6800×2000×1800m | 6800×2200×1800m |

| Max. Speed | 8000 pcs/h | 8000 pcs/h |

Specification may be slightly adjusted for better use, without prior notice.

- 1. Carton blank feeding station

- 2. Aligning system

- 3. Gluing station

- 4. Control system

- 5. Film cutting system

- 6. Punching unit

- 7. Window patching station

- 8. Scoring and creasing station

- 9. Film feeding unit

- 10. Conveying unit

- 11. Delivery table

Belt conveyor is driven by servo motor for bottom feeding of carton blank, ensuring continuous feeding. The feeding speed can be adjusted through the operator interface according to the size of carton blank.

- The base material can be adjusted horizontally.

- It adopts dual pneumatic punching and scoring devices and allows for front and back or left and right adjustment. The punching waste can be collected.

- Punching pressure is adjustable and the creasing depth can be adjusted according to the foil thickness and use of the film.

- Servo-driven feeding system allows for free adjustment of the film length without stopping the machine.

- File cutting mode: the upper and lower cutter moves alternately.

- Special patching device ensures a margin of error of the line creasing is no more than 0.5mm.

- Data memory function

- The gluing station utilizes a 304 stainless steel gluing roller, and is equipped with a scraper device, which allows for quick adjustment of the thickness and width of the glue, while reducing waste of glue.

- Users can use flexo templates for gluing accurately and efficiently. Gluing position can be adjusted freely left and right. The front and back adjustment can be done through a phase regulator without stopping the machine.

- The gluing will lift off automatically to avoid gluing on the belt in case of no carton blank.

- The glue is dispensed automatically from an inverted container, which makes cleaning and maintenance easier.

The delivery table uses a blet conveyor and stacked device to collect the patched cartons.

Looking for more information? We are here to help.

Yes, different materials will determine the printing effect, structural integrity, moisture resistance, and other important factors of the packaging box. This is crucial to consider when making window boxes.