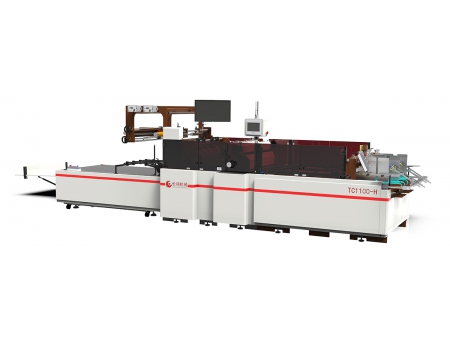

Servo Driven Dual Lane Window Patcher, TC-1100H

- Normal window

- Form slitting

- Intermittent length slitting

ChangHong servo driven dual lane window patcher is capable to run two production lines at a time, delivering a maximum production speed of 10,000 pcs/h. If the carton is too large, the operator can decide to use single-line production mode. Equipped with a PLC control system, the gluing and filming position can be adjusted by inputting the parameters on the touch screen without stopping the machine. Currently, this high speed window patcher has been widely used in the window patching process of tissue boxes, cosmetic boxes, gift boxes, and craft boxes, among other cardboard boxes.

| Model | |

| Max. Blank Size | 960×1100mm |

| Min. Blank Size | 200×150mm |

| Max. Thickness of Corrugated Board | 6mm |

| Max. Thickness of Cardboard | 200-500g/m² |

| Max. Patch Size (L×W) | 600×800mm |

| Min. Patch size(L×W) | 40×40mm |

| Film Thickness | 0.03-0.25mm |

| Max. Speed (Small Size Blank) | Single lane operation ≤20.000 pcs/h Double lane operation ≤40.000 pcs/h |

| Max. Speed (Medium Size Blank) | Single lane operation ≤15.000 pcs/h Double lane operation ≤30,000 pcs/h |

| Max. Speed (Large Size Blank) | Single lane operation ≤10,000 pcs/h |

| Small-Size Blank Length | 120-280mm |

| Medium-Size Blank Length | 220-460mm |

| Large-Size Blank Length | 420-960mm |

| Blank Width (Single Lane Operation) | 150-400 mm |

| Blank Width (Double Lane Operation) | 150-400mm |

| Accuracy | ±1mm |

| Machine Dimensions | 6800×2100×1900mm |

| Machine Weight | Approx. 5500 kg |

| Total Power | 14kW |

| Actual Power | About 60% of total machine power |

Specification may be slightly adjusted for better use, without prior notice.

- Fully servo-driven carton blank feeding system and multiple feeding modes: it can be adjusted according to the carton size and thickness to ensure quick and stable entry of the carton into the conveyor belt. Dual lane window patcher features higher production efficiency due to two lanes operation.

- The dual lane feeder is driven by 9 servo motors, which provides high accuracy, good stability, and convenient adjustment.

- The dual lane feeder comes with data memory function.

- The glue roller is adjustable in height and position (right or left) to ensure quick changeovers. The lifting device can lift up when there are no cartons entering the machine, preventing the glue roller from contacting the conveyor belt. When the machine stops, the glue roller automatically runs at a low speed to prevent the glue from drying out.

- This window patcher is equipped with an integrated cleaning system including a movable scraper, allowing for easy and fast cleaning within 2 minutes.

- Glue roller is made of 304 stainless steel for better corrosion and wear resistance.

The quick change of the cold glue stencil allows for fast adjustments to accommodate different products. Simply replacing the stencil enables product switching. The cold glue roller is controlled by a servo system, allowing for computer-adjusted positioning of the stencil in the front and back, ensuring fast and precise adjustments.

- Alignment System

- Feeding System

- Delivery System

The carton blanks will be transferred onto the conveyor belt in overlapped form.

Looking for more information? We are here to help.

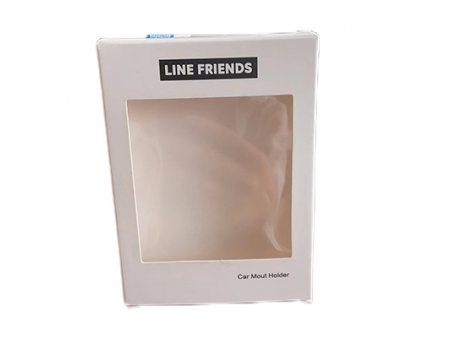

Cardboard boxes have a wide range of advantages that make them popular in product packaging across almost all industries. Some of the advantages include:

- Excellent strength and durability

- Easy assembly and recyclability

- Protective cushioning and stackability

- Most importantly, provides visual access to the packed product