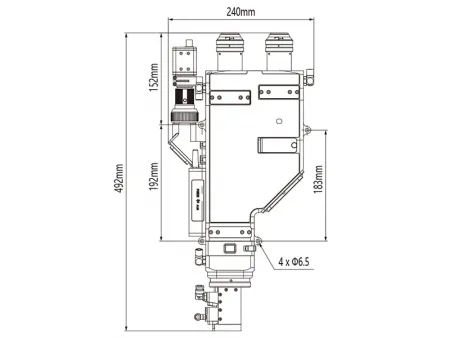

8kW Dual-Wavelength Hybrid Laser Welding Head

LWY08A0

Laser welding head for welding highly reflective metals

LWY08A0

Laser welding head for welding highly reflective metals

The 8kW dual-wavelength hybrid laser welding head is engineered for the challenges of welding highly reflective metals such as copper and aluminum. By combining fiber laser and semiconductor laser sources, it significantly improves absorption rates, delivering stable, high-quality welds even on difficult materials.

This hybrid laser welding head integrates collision protection and contamination monitoring, ensuring uninterrupted operation and fast recovery in case of disruptions. Built-in safety and alarm functions allow operators to address issues quickly, minimizing downtime and safeguarding production efficiency.

| Model | LWY08A0 |

| Rated Power | 8kW |

| Wavelength | 1080nm 915nm |

| Semiconductor Collimation Length | 100mm |

| Fiber Collimation Length | 100mm/150mm/200mm |

| Focal Length | 200mm/250mm/300mm |

| Blowing Method | Coaxial/paraxial |

| Auxiliary Gas Pressure | ≤1MPa |

| Weight | 9.6kg |

With its dual-wavelength design, this hybrid welding head is ideal for medium to high-power welding of stainless steel, carbon steel, copper, and aluminum alloys. Its versatility makes it suitable for industries requiring both strength and precision, from automotive manufacturing to energy storage and electronic components.

Dual-wavelength synergy (1080 nm 915 nm) enhances absorption in highly reflective metals such as aluminum, delivering deeper penetration, brighter seams, and consistently high-quality welds.

Equipped with coaxial / air-knife blowing assembly, the head safeguards the optics from impact, allowing non-destructive collisions and rapid recovery for continuous operation.

A spiral adjustment shifts the focal point by 1 mm with each 360° turn, providing accurate and repeatable focusing control.

Real-time contamination detection triggers alarms and automatic shutdown to prevent defective welds and protect the laser head from damage.