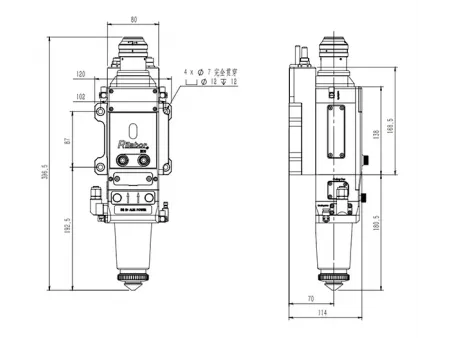

8kW Fiber Laser Cutting Head

GM08B

Auto focus laser cutting head for flat/bevel cutting of medium-thick metal sheets and metal tubes

Our auto-focus fiber laser cutting heads are designed for medium-thickness metal, covering flat cuts on plate and bevel cuts on tubes and profiles. They include a built-in 5G communication module that streams live status for remote monitoring, so operators can check assist-gas pressure and the protective-window condition in real time. If the sensor detects contamination on the protective window, the head’s monitoring module signals the laser cutting machine controller, which triggers an alarm and stops the cut to protect the optics. A drawer type window protection unit with front access makes service quick, which reduces downtime and keeps production moving.

| Type | Auto Focus Fiber Laser Cutting Head |

| Model | GM08B |

| Interface Type | QBH,QD,G5 |

| Wavelength | 1080±10nm |

| Rated Power | ≤8kW |

| Focal Length | 200mm/250mm |

| Collimation Length | 100mm |

| Focusing Range | -35mm~ 30mm / -50mm~ 50mm |

| Centering Adjustment Range | ±1.5mm |

| Focusing Speed | 100mm/s |

| Auxiliary Gas Pressure | ≤3MPa |

| Weight | 5kg |

Widely used for flat cutting on metal sheets and bevel cutting on tubes and profiles. They process carbon steel, stainless steel, and other common metals with consistent, clean edges.

With the add-on 5G module, live laser head data, assist-gas pressure, protective-window condition, and alarms, can be viewed remotely, so operators see issues early and act before quality drifts.

A drawer type front bay gives direct access to the protective window and wear parts. Changing such spare parts take minutes, which cuts downtime and helps keep the optics clean.

A sensor tracks contamination on the protective window. It first prompts a timely change; if levels exceed the limit, the controller triggers an alarm and stops the cutting process to protect the optic lenses.

Continuous pressure readout helps set and hold the right process window, supporting stable cutting on metal sheets and on tubes.

A breakaway crash design uses a sacrificial element that releases on impact to shield the head; after a minor bump, the head resets quickly so production can resume with minimal interruption.