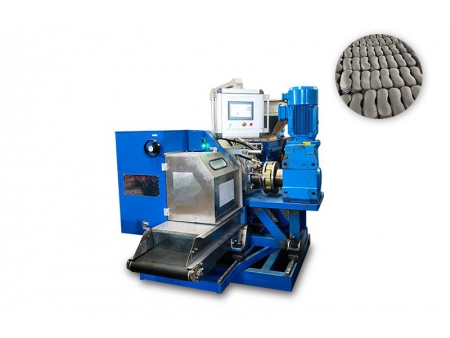

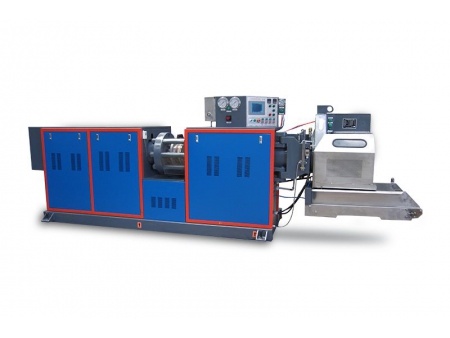

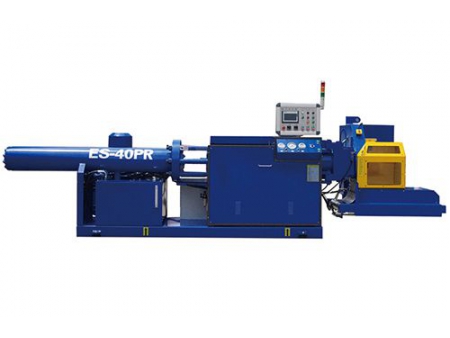

Cold Feed Rubber Precision Preformer, DRLQ Series

Request a Quote

Continuous rubber preformer combining screw extruder and gear pump for making rubber blanks

The cold feed rubber precision preformer is a highly efficient and precise rubber blank manufacture machinery. It operates by feeding raw material strip into a pin screw and gear pump under room temperature, which cuts the material into a set shape and size. This device is a great fit for producing a variety of rubber/silicone blank and has a small occupied area, autonomous functioning, streamline production process and easy operation. Finished products range from rings, strips, circles to miscellaneous rubber items, sealant components, oil seals, valves, tennis balls, soles, etc.

Specification

| Items | Unit | DRL75-Q | DRL90-Q | DRL120-Q | DRL150-Q |

| Screw diameter | mm | 75 | 90 | 120 | 150 |

| Screw L/D ratio | L/D | 12:1 | 8:1 | 8:1 | 6:1 |

| Screw rotation speed | Rpm | 0-60 | 0-60 | 0-60 | 0-40 |

| Speed of gear pump | Rpm | 0-40 | 0-40 | 0-40 | 0-40 |

| Cutter speed | Rpm | 0-400 | 0-400 | 0-400 | 0-400 |

| Total power | KW | 38 | 55 | 75 | 115 |

| Max. extrusion pressure | MPa | 35 | 35 | 35 | 35 |

| Temperature controlled by mould temperature machine | °C | 20-90 | 20-90 | 20-90 | 20-90 |

| Max. die diameter | mm | 80 | 190 | 190 | 190 |

| Rubber blank weight range | g | 0.1-300 | 0.1-3000 | 0.1-6000 | 0.1-6000 |

| Weight accuracy (99% compound) | Percentage | ≤±0.5% | ≤±0.5% | ≤±0.5% | ≤±0.5% |

| Max. capacity | kg/h | 120 | 250 | 450 | 750 |

| External dimension (L*W*H) | m | 3.5×1.5×1.65 | 4.0×1.7×1.65 | 4.3×1.7×1.65 | 4.5×1.7×1.65 |

| Weight | t | 4.2 | 6.5 | 8.0 | 10.0 |

| Feeding type | Cold/Hot | Cold | Cold | Cold | Cold |

Advantages

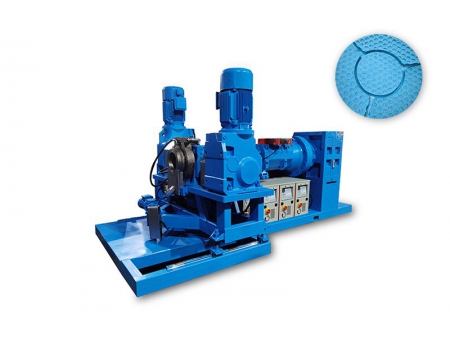

- Gear pumps can be operated with a single drive or dual drive system.

- The cold feed screw preformer is utilized to cut the normal temperature strip rubber compound into the customer's desired shape and weight continuously. The weight accuracy of the rubber blank is monitored to within ± 0.5% via the control of a gear pump.

- Quick product setup with PLC control and process parameters database.

- A separation structure using an electric motor supports the gear pump, screw and machine head, simplifying rubber raw material replacement and conducting easier cleaning.

- Both the mesh cover and conveyor are wrapped with stainless steel to protects against contamination.

- Using a scales feedback system to ensure automatic caliberate of blank weight.

- Error alarm with an icon displaying fault location, acting as regular reminders for workers to conduct spot-checks and calibrate the weight of rubber blanks.

- Reliable systems and interlock head and cutter can help prevent work-related injuries.

- The searchlight is a useful tool for cleaning, helping to ensure that all those tricky, hard to reach spots don't get overlooked.

- Both system and extrusion pressures are intuitively displayed on the touch screen.

- When creating a prototype of a new product, having a PLC in operation provides useful data that can be used to streamline the process.

- Stainless steel sealing of all machine heads prevents rubber from spilling onto the ground, resulting in decreased pollution, as well as conserving the raw material.

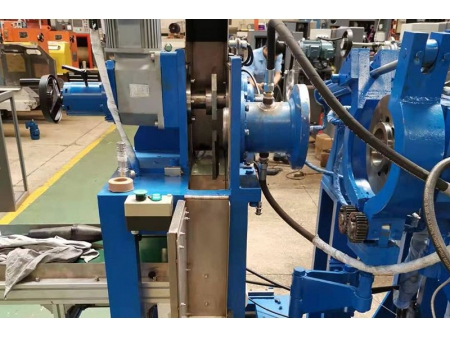

Details

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos