Cold Feed Rubber Preformer

- Rubber O-rings

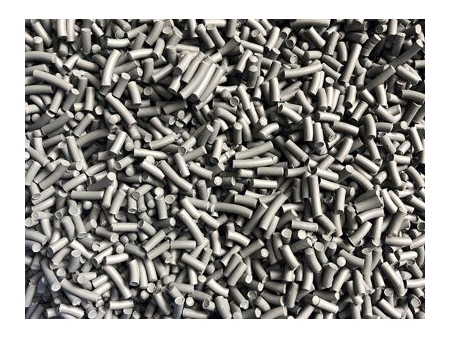

- Rubber pellets

- Thin round rubber discs

Cold feed extruder for making rubber blanks

The cold feed rubber preformer is a versatile rubber processing machine integrating multiple functions such as filtering, extrusion, cutting, automated weighing, and counting. Unlike its hot feed counterparts, the cold feed preformer employs a continuous cold feed approach. This innovative approach not only boosts rubber product manufacturing efficiency but also significantly reduces labor intensity.

Our cold feed rubber preformers are available in two distinct structures: one with a gear pump and another without (screw-type). The gear pump structure allows for precision preforming of various rubber materials, ensuring stable extrusion under controlled pressure, and guaranteeing precise blank weight. While the screw-type preformer produces rubber blanks with weight precision closely tied to shape, size, type of rubber, and hardness. This option is ideal for production using standard rubber materials or primary rubber products with less stringent weight accuracy requirements.

| Model | | | | |

| Barrel and Screw | ||||

| Screw Diameter | 50mm | 75mm | 90mm | 120mm |

| Length/Diameter Ratio (LD) | LD=12:1 | L/D=12:1 | LD=12:1 | L/D=12:1 |

| Gearbox | ||||

| Reducer Ratio | 16:1 | 16:1 | 20:1 | 20:1 |

| Feeding Motor Power | 7.5 kW-6p | 30 kW-6P | 37 kW-6p | 55 kW-6P |

| Cutting System | ||||

| Max. Die Diameter | 68mm | 100mm | 127mm | 190mm |

| Max. Blank Weight | 500g | 1000g | 2000g | 2000g |

| Output | 70kg/hr | 180kg/hr | 300kg/hr | 550kg/hr |

| Cutter Speed | 30-400 (r/min) | 30-400 (r/min) | 30-400 (r/min) | 30-400 (r/min) |

Cold preformer offers several advantages, and some of the key ones include:

- Continuous feeding

- No need for preheating with a milling machine