Palletizing Robot

- Features

- Specifications

- Options

At Hwashi Technology, our palletizing robot are available in 6-axis robotic palletizer and 4-axis robotic palletizer, which can replace manual labor in automated handling operations. Palletizing robots can be equipped with different grippers to handle workpieces of various shapes and conditions, greatly reducing the physical burden on human workers. Robotic palletizing & stacking system are widely used in tasks such as automation of machine tool loading and unloading, automatic production lines for stamping machines, automatic assembly lines, palletizing and stacking, and container handling.

| DOF | 6 axis / 4 axis |

| Arm Reach | 1500-3150mm |

| Payload | 8kg-300kg |

| Operating Power | 10-20kW |

| Repeatability | ±0.2mm |

| Capacity | 800-1200pcs/hour |

- Simple structure, low failure rate, and easy maintenance.

- Minimal main components and spare parts, resulting in low maintenance costs.

- Energy-saving and environmentally friendly, with low power consumption, only 1/5 of equivalent mechanical palletizers.

- Small footprint, adaptable to various working environments.

- High safety level, capable of stable operation over prolonged periods.

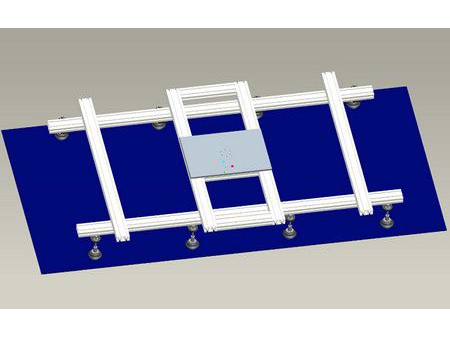

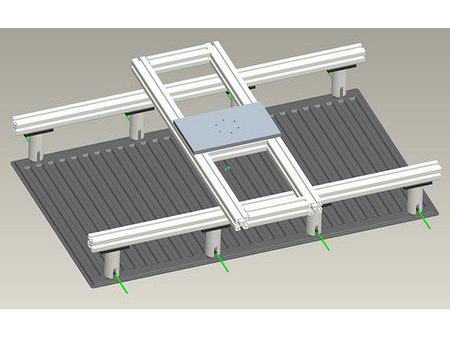

- Suction cup gripper

Mainly used for handling light flat panel materials.

- Magnetic gripper

Mainly used for handling metal carbon steel sheets or boxes, which are heavier products.

- Pneumatic gripper

Mainly used for handling heavy products that are easy to grip.

- Bag gripper

Mainly used for handling bagged products such as sandbags, cement bags, and flour bags.

- Multi-head gripper

Mainly used for gripping and placing various small parts, customized grippers are designed according to different products.