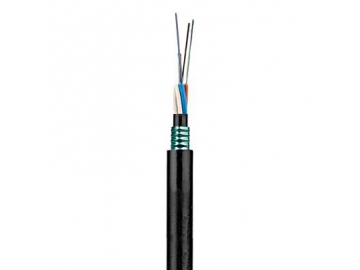

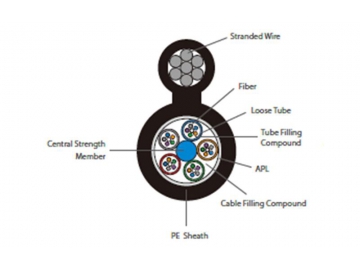

Figure 8 Armored Fiber Optic Cable

Description

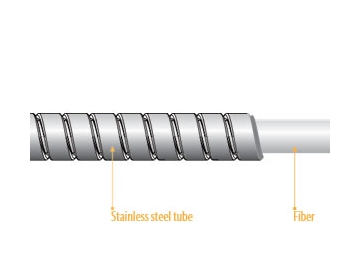

Ingo provides figure 8 armored fiber optic cables with a central tube bundle sheathed into a Y or S shape. This fiber operatic cable is most often used in self-supporting aerial laying. The structure combines with fiber optics with a diameter of 250μm inside the loose tube made of highly modulus materials. The loose tube is filled with a waterproof compound, and at the center of the cable core is a metallic strengthening core. The loose tube strands and the central strength member form a compact and round cable core. After being longitudinally wrapped by a layer of APL, the cable core is integrated into a figure 8 PVC jacket with steel wires.

Standard

| cable type (increase by 2 fibers) | fiber count | tubes | fillers | cable diameter (mm) | cable weight (kg/km) | tensile strength long/short term (N) | crush resistance long/short term (N/100mm) | bending radius dynamic/static (mm) |

| GYTC8A 2-6 | 2-6 | 1 | 4 | 6.8*9.2*18.0 | 214 | 600/1500 | 300/1000 | 10D/20D |

| GYTC8A 8-12 | 8-12 | 2 | 3 | 6.8*9.2*18.0 | 214 | 600/1500 | 300/1000 | 10D/20D |

| GYTC8A 14-18 | 14-18 | 3 | 2 | 6.8*9.2*18.0 | 214 | 600/1500 | 300/1000 | 10D/20D |

| GYTC8A 20-24 | 20-24 | 4 | 1 | 6.8*9.2*18.0 | 214 | 600/1500 | 300/1000 | 10D/20D |

| GYTC8A 26-30 | 26-30 | 5 | 0 | 6.8*9.2*18.0 | 214 | 600/1500 | 300/1000 | 10D/20D |

| storage/operating temperature: -40℃ to +70℃ | ||||||||

| G652 | G655 | 50/125UM | 62.5/125UM | ||

| attenuation (+20℃) | @850nm | ≤0.30db/km | ≤3.3db/km | ||

| @1300nm | ≤1.0db/km | ≤1.0db/km | |||

| @1310nm | ≤0.36db/km | ≤0.40db/km | |||

| @1550nm | ≤0.22db/km | ≤0.23db/km | |||

| bandwidth (A grade) | @850nm | ≥500MHz.km | ≥200MHz.km | ||

| @1300nm | ≥1000MHz.km | ≥600MHz.km | |||

| numerical aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| cable cut-off wavelength (λcc ) | ≤1260nm | ≤1450nm | |||

| application: self-supporting aerial laying | |||||

- The steel wires have an extremely high tensile strength that is convenient for self-supporting aerial laying.

- The figure 8 armored fiber optic cable has a great mechanical behavior and temperature characteristics.

- The loose tube materials feature a great hydrolysis resistance and relatively high strength.

- A special grease fills the loose tube in order to offer critical protection for the fiber optic.

Use the following measures to ensure the waterproof performance of the optical cables

- Using the single steel wire as central strength member.

- Filling up the loose tube with special waterproof compound.

- 100% cable core filling

- Using APL as moisture barrier.