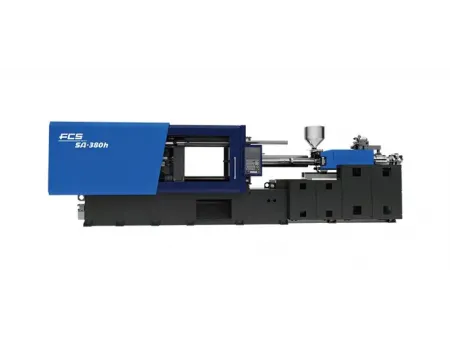

Thin-Wall Injection Molding Machine

The thin-wall injection molding machine is a newly launched product manufactured by FCS, designed specifically for producing thin-walled packaging. This injection molding equipment integrates a high-performance servo-hydraulic system, which enables energy savings of 30%-70%. It features a proportional valve structure for rapid response and precise positioning with cycle times as short as 1 ms. Temperature variations are tightly controlled within ±1°C using PID temperature control, and the clamping force ranges from 170 to 600 tons.

- Injection stroke 190mm-230mm

- Injection capacity 217g-592g

- Injection pressure 1651kgf/cm²-1712kgf/cm²

- Injection rate 419g/s-1328g/s

- Clamping force 170tonf-600tonf

- Clamping stroke 430mm-820mm

- Pump motor power: 58kW-63.5kW 63.5kW 37kW

- Electric heating power: 10kW-32.6kW

- Drive system: hydraulic

Ideal for injection molding of food packaging, plastic trays, plastic cups, and plastic medical products.

Samples of Plastic Injection Molded Parts- Injection molding of thin wall food container

- Injection molding of LSR PC pen holder

Features a high-rigidity mold plate that minimizes elastic deformation and lowers the clamping force needed. Equipped with high-speed proportional valves enhances mold response and positioning accuracy, reducing cycle times.

The standard configuration comprises a high-performance servo system, achieving the fastest response times of up to 40 m/s. Its modular design simplifies maintenance and supports dual-circuit operations to maximize cycle efficiency.

The injection molding system is equipped with pipelines that have undergone a non-welding process to reduce the risk of oil leaks and increase the cleanliness of the oil path, thereby extending the high speed plastic molding machine's lifespan.

The injection platform and base move along dual linear rails, reducing friction resistance and enhancing precision. It features a medium-inertia single-cylinder injection structure for quick start-up and high repeatability.

Standard equipped with infrared nano heaters for rapid heating, excellent heat retention, and over 30% energy savings. Utilizes PID temperature control to maintain accuracy within ±1°C. Features a large L/D ratio and high-mixing screw for superior plasticization efficiency.

Standard equipped with the KEBA control system. Offers an operation mode scan cycle within 1ms. Designed with an ergonomic layout. Includes comprehensive data and image monitoring functions.

- Equipped with a KEBA control system for streamlined operations

- Action scanning period is less than 1ms

- Ergonomically designed to fit human operation standards

- Features infrared nano-heating rings that heat quickly and retain heat effectively, saving over 30% of energy

- Temperature control is managed via PID, maintaining precision within ±1°C

- Utilizes a large L/D ratio screw that enhances mixing and plasticizing efficiency

| Model | Unit | |||||

| Injection Unit | Type | - | 400 | 770 | 1000 | 1100 |

| Screw diameter | mm | 40 | 50 | 58 | 60 | |

| Screw stroke | mm | 190 | 230 | 230 | 230 | |

| Theoretical shot volume | cm³ | 239 | 452 | 608 | 650 | |

| Shot weight of injection (PS) | gram | 217 | 411 | 553 | 592 | |

| Injection pressure | kgf/cm² | 1663 | 1710 | 1707 | 1712 | |

| Injection speed | mm/seo | 365 | 395 | 475 | 515 | |

| Injection rate | cm3/sec | 460 | 778 | 1260 | 1459 | |

| Mold Clamping Unit | Mold camping force | tonf | 170 | 290 | 460 | 600 |

| Mold camping stroke | mm | 430 | 550 | 750 | 820 | |

| Mold thickness | mm | 180~520 | 220~580 | 280~730 | 300~850 | |

| Tie bar spacing (H×V) | mm | 470×410 | 580×515 | 720×720 | 830×750 | |

| Mold platen (H×V) | mm | 745×655 | 875×875 | 1090×1090 | 1230×1150 | |

| Ejector stroke | mm | 135 | 140 | 140 | 180 | |

| Ejector force | tonf | 6.7 | 8.8 | 8.8 | 13 | |

| Electrical Equipment | Max. pump driving motor | kW(380V) | 58 | 46.2 46.2 | 63.5 63.5 | 63.5 63.5 37 |

| Heater capacity | kW | 10 | 20.4 | 32.6 | 33 | |

| General | Machine dimensions (L×W×H) | mm | 4900×1430×2100 | 6590×1630×2120 | 7850×1950×2080 | 8610×2170×2200 |

| Oil tank capacity | liter | 260 | 500 | 580 | 630 | |

| Machine weight | ton | 5.5 | 11 | 18.5 | 26 | |