CNC Jig Grinder

Request a Quote

NJ-MK4280/1

Coordinate grinding machine with continuous path capability for creating precise holes and complex contours in mold and die making

This CNC jig grinder supports continuous-path machining for hardened mould cavities, templates and punches, generating precise curves using linear and circular approximation. It also performs high-accuracy point-to-point grinding for hardened coordinate hole systems with tight spacing requirements.

The jig grinding machine uses a SIEMENS CNC system to control the X, Y, Z, W, U and C axes, with three-axis simultaneous interpolation. X, Y, Z and W axes are fitted with HEIDENHAIN high-accuracy linear scales to ensure consistent positioning and stable linear-axis precision.

Features

High Precision

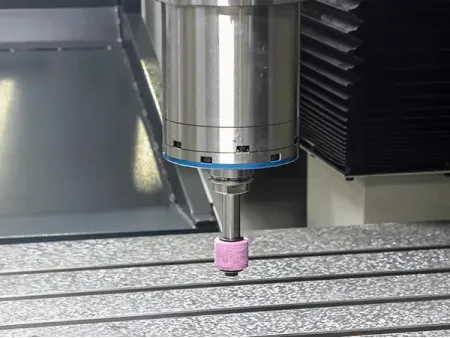

Hydrostatic planetary spindle

Hand-scraped guideways and table surfaces, with over 1500 hours of manual scraping

- Hole-spacing accuracy: ±0.003 mm

- X/Y-axis positioning accuracy: 0.0025 mm, repeatability: 0.0015 mm

- Spindle radial runout < 0.0005 mm (four times higher stability)

- Maximum spindle radial stiffness: 250 N/μm (five times higher)

- Achievable roundness: up to 0.5 μm

- Simplified structure allowing both linear movement and rotary motion of the spindle

High Efficiency

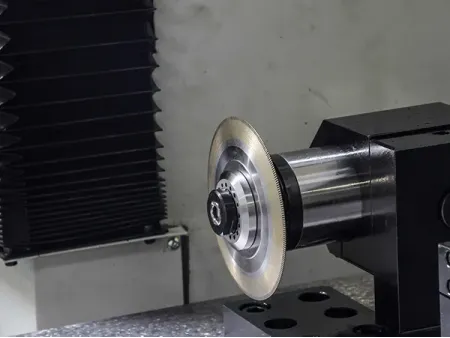

Disc-type dresser

- Z-axis driven by dual linear motors

- High-speed grinding spindle up to 70,000 r/min

- Spindle power: 2 kW

- HSK-E25 tool interface

- Optional workpiece probing

- Z-axis rapid traverse: 26 m/min

- Z-axis reciprocating frequency up to 300 strokes/min

- Z-axis repeatability: 0.002 mm

- Dresser wheel diameter: Ø120 mm

- Dresser speed: 8000 r/min, power: 0.8 kW

Intelligent Functions

Automatic wheel measurement

Workpiece probing

Optional Configurations

- Automatic wheel measurement

- Workpiece probe

- Tool probe (TS27R)

- 12-position tool magazine for building a fully integrated “jig grinding center”

Sample Display

Technical Specifications

| Worktable | Table width (mm) | 860 | |

| Table length (mm) | 1440 | ||

| X-axis longitudinal travel (mm) | 1300 | ||

| Max. table load capacity (kg) | 800 | ||

| X-axis positioning accuracy (mm) | Bidirectional positioning accuracy | 0.004 | |

| Repeatability | 0.002 | ||

| Grinding Headstock | Y-axis transverse travel (mm) | 800 | |

| W-axis vertical travel (mm) | 635 | ||

| Distance from slide end face to table surface (mm) | Max. | 905 | |

| Min. | 100 | ||

| Y-axis positioning accuracy (mm) | Bidirectional positioning accuracy | 0.004 | |

| Repeatability | 0.002 | ||

| Grinding Wheel | Z-axis reciprocating stroke length (mm) | 170 | |

| Z-axis reciprocating stroke speed (m/min) | 0.01–22 | ||

| Grinding wheel motor speed (10⁴ r/min) | 0.4–4 | ||

| Planetary Spindle | Planetary spindle speed (r/min) | S-axis | 5–300 |

| C-axis | ≤30 | ||

| Planetary Grinding Feed | U-axis slide CNC feed range (mm) | -3 to 47 | |

| Total power input (kVA) | 60 | ||

| Machine weight (kg) | Approx. 16000 | ||