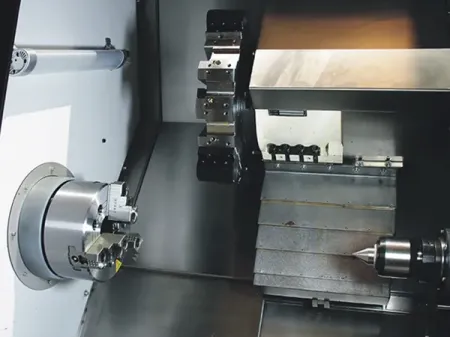

Horizontal CNC Lathe

Request a Quote

CKD6140A

This is a high-efficiency, high-precision two-axis horizontal CNC lathe with a rigid 45° slant-bed structure. The one-piece cast-iron bed uses low-stress, high-rigidity material to ensure stability. Precision linear guideways and ball screws deliver accurate positioning, fast feed rates and long-term accuracy retention. The horizontal CNC lathe is equipped with an 8-station hydraulic servo turret, an 8-inch power chuck and a hydraulic tailstock, allowing it to handle complex multi-step turning tasks and automated machining workflows. It is suitable for a wide range of turning operations on disc and shaft components, including external turning, facing, taper turning, threading and arc profiling.

Features

- The high-strength one-piece cast-iron base provides strong rigidity with excellent vibration damping and minimal deformation.

- The 45° slant-bed design improves chip removal efficiency and operator accessibility, supporting smooth machining operations.

- X/Z axes use precision linear guideways and ball screws from specialized manufacturers, ensuring high accuracy, rigidity and fast axis movement.

- Standard Taiwan-made 8-station hydraulic servo turret enables fast, accurate tool indexing and continuous multi-process machining.

- The 8-inch power chuck and rotary hydraulic cylinder ensure reliable and stable workpiece clamping.

- The hydraulic tailstock supports Z-axis driven movement and programmable sleeve travel, with both manual and program-controlled modes.

- Full-enclosure guarding keeps oil, coolant and chips contained for clean operation, smooth chip discharge and easy maintenance.

- A standard coolant tank collects chips efficiently, and optional accessories can be added to support fully automated machining.

Sample Display

Bushing components

Technical Specifications

| Max. swing over bed (mm) | Ø400 | |

| Max. machining diameter (mm) | Disc workpieces | Ø360 |

| Shaft workpieces | Ø200 | |

| Max. turning length (mm) | 500 | |

| Spindle center height (mm) | 1000 | |

| Spindle speed (r/min) | 100–4000 | |

| Spindle motor power (kW) | 11 | |

| Chuck size (inch) | 8 | |

| Spindle nose type | A2-6 | |

| X/Z-axis travel (mm) | 200/530 | |

| X/Z-axis rapid traverse (m/min) | 20/20 | |

| Tailstock travel (mm) | 380 | |

| Tailstock quill stroke (mm) | 110 | |

| Tailstock quill diameter (mm) | Ø80 | |

| Tailstock quill taper (mm) | MS NO.4 | |

| Turret stations | 12 | |

| Turning tool size (mm) | 25×25 | |

| Max. boring bar diameter (mm) | Ø32 | |

| CNC system | FANUC 0i TF Plus | |

| Control mode | Semi-closed loop | |

| Spindle feedback element | Encoder | |

| Linear axis feedback element | Servo motor with built-in encoder | |

| X/Z motor power (kW) | 1.2/1.8 | |

| Coolant pump motor power (kW) | 0.37 | |

| Coolant tank capacity (L) | 180 | |

| Lubrication motor power (kW) | 0.025 | |

| Lubrication tank capacity (L) | 1.8 | |

| Hydraulic system pressure (MPa) | 4 | |

| Hydraulic tank capacity (L) | 50 | |

| Overall dimensions (L×W×H) (mm) | 2820×1500×1700 | |

| Machine weight (kg) | 3000 | |