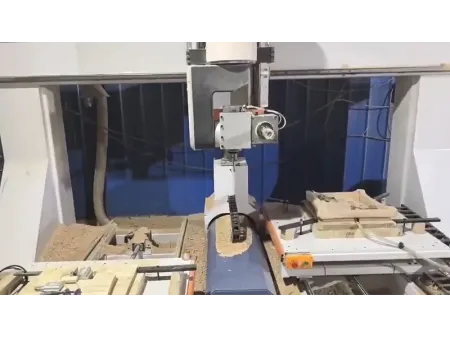

Double Table 5 Axis CNC Wood Lathe

//Woodworking Machinery

CNC machining center with 5 interpolated axes and 2 independent work tables for manufacturing solid wood furniture

- Spindle speed18000r/m

- Frequency converter15kW

- Machine dimensions4000×2100×3500mm

- Machine weight5700kg

Double table 5 axis CNC wood lathe is designed for continuous, high-precision machining of complex wooden components. With two independent worktables, this system enables seamless operation, while one table is actively processing, the other can be loaded or unloaded. The tables can also operate simultaneously to handle large or intricate workpieces, significantly increasing production efficiency without compromising accuracy.

- X/Y/Z axes travel1200mm/1000mm/600mm

- Control systemTaiwan 8-axis control system

- Driving motor1300W servo motor

- Work table2 worktables (can be integrated into one table)

- Spindle speed18000r/m

- Guide rail30 Taiwan square rail sliding block

- Frequency converter15kW

- CableShield cable

- Voltage380V

- Oil lubricationAutomatic oil lubrication system

- AccessoriesBlade, tool holder, tool box

- Machine dimensions4000×2100×3500mm

- Machine weight5700kg

The double table 5-axis CNC machining system is ideal for the production of high-end solid wood furniture components, particularly those featuring curved profiles and sculpted surfaces. It is widely used for crafting chair backs and legs, table legs with artistic contours, bed posts and frames. Its ability to perform precision joinery such as mortise-and-tenon structures enhances both structural integrity and aesthetic quality, making it a valuable asset for manufacturers seeking quality and efficiency.

- Integrated tool length measuring improves the precision of tool setting, minimizing deviation and reducing setup time during tool changes.

- Each worktable is equipped with square vacuum chucks and pneumatic clamps, ensuring fast, secure workpiece fixation and reliable processing, even with irregular or heavy components.

- The full 5-axis interpolated machining supports comprehensive multi-directional operations, including milling, engraving, drilling, and sawing, on flat, curved, inclined, and 3D contoured surfaces.

- Built on a modular CNC platform, the system offers strong functionality and ensures precise positioning across all workpiece surfaces. Capable of processing rotational geometries and freeform surfaces in a single setup, it supports both 2D and 3D operations with high consistency.

- Enables one-time clamping and complete processing of multiple surfaces in five-dimensional space, reducing repositioning and ensuring machining efficiency for complex components.