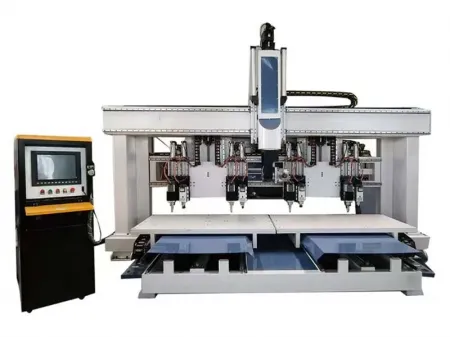

Four Table 5 Axis CNC Machining Center

//Woodworking Machinery

5 axis CNC working center with four worktables for machining large wood workpieces

- Max. machining length680×800mm

- Servo controllerAbsolute value encoder

- Switch/relaySchneider, France

- Machine dimensions (L×W×H)4500L×3500W×2800H mm

With four independently operable worktables, the four table 5 axis CNC machining center is designed for uninterrupted, high-capacity production. The woodworking machine supports continuous processing as one table handles machining while others are used for loading and unloading. It also allows all four tables to operate in unison for large or complex workpieces, offering exceptional flexibility and productivity in demanding woodworking environments.

This 4 table woodworking machining center is ideal for manufacturing intricate solid wood components and is also well-suited for panel furniture production involving complex edge shaping, decorative carving, and precision hole placement. Its ability to accommodate diversified design requirements makes it an effective solution for both structural and ornamental woodworking needs.

| Model | ||

| Number of worktables | 4 (vacuum adsorption tables) | 4 |

| Max. machining length | 680×800mm | |

| Motion travel | A-axis(machining tool shaft):0-360° | |

| B-axis(machining table):±91° | ||

| Max. speed | X-axis:30m/min | X-axis:30m/min |

| Y-axis:30m/min | Y1/Y2-axis:50m/min | |

| Z-axis:25m/min | Z-axis:25m/min | |

| Numerical control system | Taiwan LNC | Taiwan HUST |

| Motorized spindle | 7.5kW×8pcs (high-speed water-cooled double head spindle motor ER32)16 tools for alternate machining | |

| Servo controller | Absolute value encoder | |

| Frequency converter | High performance 15kW×2pcs | High performance 30kW×2pcs |

| Spindle cooling method | Chiller water cooling | |

| Linear guide | Precision linear guide (Taiwan Yintai PMI or HTPM) | |

| Transmission | X-axis precision ball screw Y-axis precision ball screw Z-axis precision ball screw | |

| Pneumatic components | AirTAC Taiwan | |

| Cable and drag chain | High speed heavy load cable and drag chain | |

| Switch/relay | Schneider,France | |

| Machine dimensions (L×W×H) | 4500L×3500W×2800H mm | |

- The worktables are equipped with pneumatic clamps and square vacuum suction systems, enabling fast and secure workpiece fixation for stable processing.

- The five-axis configuration allows for comprehensive spatial and irregular surface machining, completing complex shaping tasks efficiently.

- It can handle a variety of rotational surfaces and complete five-sided machining in a single setup, supported by a modular hardware platform that ensures precision across all workpiece surfaces.

- The machine processes flat, curved, inclined, and angled surfaces as well as 2D and 3D contours, with one-time clamping that enables simultaneous five-axis milling, engraving, drilling, and sawing from multiple spatial directions.