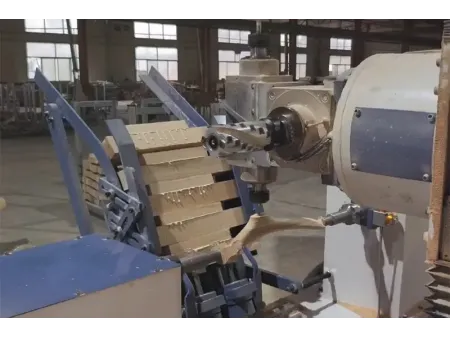

5 Axis CNC Wood Lathe

//Woodworking Machinery

CNC machining center with 5 interpolated axes for turning, milling, engraving, drilling and sawing of solid wood elements

- Spindle speed 0-18000r/min

- Air pressure 0.4-0.9MPa

- Machine dimensions 2750×2200×1950mm

- Machine weight 2800kg

5-axis CNC wood lathes combine turning, milling, engraving, drilling, and sawing into a single system for solid wood components. With interpolated movement across the X, Y, Z linear axes and two rotary axes, these woodworking systems enable precise machining of curved surfaces and complex shapes in one setup. This design boosts production efficiency while ensuring high-quality finishes, even for intricate workpieces. Designed to handle multi-dimensional surfaces, 5-axis CNC work centers allow the creation of unique designs and complex components that would be challenging with standard systems. Ideal for crafting artistic details and structural elements, they provide the flexibility and precision required for advanced woodworking production.

- Max. machining length 1300mm

- Max. machining width 400mm

- Max. machining height 400mm

- Head rotation diameter 400mm

- Feeding positioning Servo control

- Head spindle power 7.5kW 4.5kW

- Spindle speed 0-18000r/min

- Total power 12.0kW

- Voltage 380V

- Air pressure 0.4-0.9MPa

- Machine dimensions 2750×2200×1950mm

- Machine weight 2800kg

Perfect for producing a variety of complex solid wood furniture components, 5-axis CNC wood lathes deliver high-precision joinery, improving both the strength and appearance of the final product. Ideal for shaping chair legs, dining table legs, sofa legs, billiard table legs, and more, these woodworking systems ensure consistent quality and performance in each piece.

- The synchronized movement across five axes handles curved and rotating surfaces with precision, completing complex multi-surface machining in a single setup.

- A modular hardware platform ensures accurate positioning of each workpiece, providing reliable and consistent results even with intricate designs.

- Supports machining of flat surfaces, curves, inclined planes, angled holes, 2D and 3D surfaces, and three-dimensional contours.

- Offers single clamping, precise positioning, and simultaneous five-axis operations including milling, engraving, drilling, and sawing. This enables efficient multi-directional machining in a single workflow, enhancing both productivity and quality for woodworking applications.

Equipped with a stepless spindle offering automatic speed adjustment and integrated braking that stops in 1.2 seconds. The spindle rotates 360° to follow drawing specifications, ensuring accurate tool adjustments. The X, Z, Y, and A axes use servo drives for precise control, fast processing speeds, and rapid traverse rates up to 20 m/min, with an automatic overload alarm for safe operation.

Equipped with flanged linear guides that provide stable support during high-volume processing, ensuring minimal vibration and preventing tool marks. This setup delivers smooth, high-quality finishes, simplifying the sanding and polishing process.

Uses a standard CNC control platform that supports G-code programming, ensuring compatibility and precision for various woodworking tasks.

Multifunctional Vacuum Chuck