4-Head 5 Axis CNC Machining Center

//Woodworking Machinery

5 axis CNC working center with four heads for simultaneous machining of multiple complex wood workpieces

- Max. machining length1200mm

- Ejector pin spacing350mm

- Machine dimensions5500×4000×3000mm

- Machine weightApprox. 7T

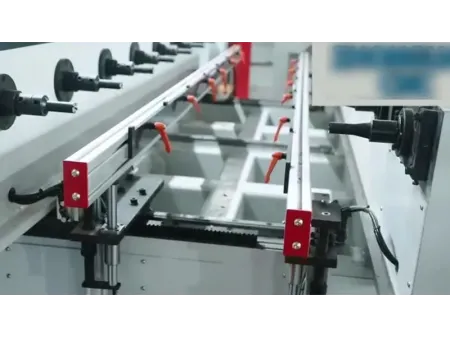

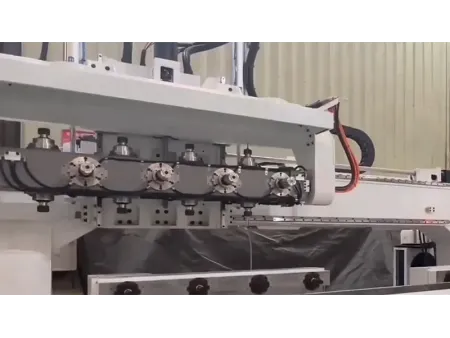

The 4-head 5 axis CNC machining center is designed for high-efficiency, multi-task production in woodworking applications. It features dual worktables and four independently controlled spindles, each equipped with an ER32 collet chuck system and a rotating tool change mechanism. This configuration supports four distinct tool rows, each capable of 360° positioning, allowing for four different operations to be completed simultaneous in a single cycle across different workpieces. It enables parallel machining of complex, high-precision wooden components, making it ideal for manufacturers seeking greater output with consistent quality.

This advanced woodworking machining center is ideal for processing a variety of solid wood components that require both turning and milling, such as furniture columns, stair parts, and legs for chairs, tables, and sofas. Its ability to carry out multiple operations across several spindles in one cycle makes it especially effective for high-volume manufacturers producing symmetrical or repetitive wood parts.

| Number of worktables | 1Nr (single worktable) | 2Nr (double worktable) |

| Max. machining length | 1200mm | |

| Ejector pin spacing | 350mm | |

| Motion travel | X-axis:590mm | X-axis:1900mm |

| Y-axis:1600mm | Y1-axis:1760mm | |

| Z-axis:500mm | Y2-axis:1760mm | |

| Z-axis:500mm | ||

| A-axis:0-360° | ||

| C-axis (turning/milling axis):continuous rotation | ||

| Numerical control system | Taiwan LNC | |

| Motorized spindle | 7.5kW×8pcs (high-speed double-head spindle) Tool collet:ER32 | |

| A/B axes | B-axis reducer:ultra precision worm gear reducer A-axis reducer:ultra precision RV reducer | |

| Servo controller | High-resolution absolute encoder | |

| High performance frequency converter | 11kW×2pcs | |

| Linear guide | Precision linear guide rail (Taiwan brand) | |

| Transmission | X-axis precision ball screw (Taiwan brand) Y-axis precision rack and pinion Z-axis precision ball screw (Taiwan brand) | X-axis precision ball screw (Taiwan brand) Y1/Y2-axis precision rack and pinion Z-axis precision ball screw (Taiwan brand) |

| Pneumatic components | AirTAC Taiwan | |

| Cable and drag chain | High speed and heavy load cable and drag chain | |

| Switch/relay | Schneider,France | |

| Machine dimensions (L×W×H) | 5500×4000×3000mm | 6000×4000×3000mm |

| Machine weight | Approx. 7T | Approx. 8T |

- Fully compatible with NC programming, the CNC programming system ensures the cutting path precisely follows the programmed tool trajectory leading to uniform surface texture and refined cutting lines across all workpieces.

- The integrated C-axis allows for continuous workpiece rotation and precise angular control of the workpiece, essential for processing cylindrical and contoured parts.

- Its five-axis control system performs turning, milling, circular carving, flat carving, routing, and drilling operations in a single setup for complex or irregularly shaped wood parts.

- The optimized tool layout reduces tool change time and supports seamless transitions between machining processes after a single clamping.

- All four heads can operate simultaneously, enabling synchronized machining of multiple components with high precision, stability, and production speed, making it ideal for high-volume production.