High Precision CNC Lathe

Request a Quote

MICRO-T400

Ultra-precision CNC turning machine with spindle runout ≤0.2μm for delivering ≤0.5μm roundness and Ra≤0.02μm surface finish

The MICRO-T400 high precision CNC lathe is built as a single-spindle mineral-cast slant-bed structure with a compact layout. It integrates static-pressure built-in spindle technology, hydrostatic guideways, a hydrostatic tailstock and high-precision drive systems (ultra-precision ball screws or linear motors), supported by vibration- and deformation-resistant bed construction. The ultra-precision CNC turning machines hardened materials from 58-68 HRC and serves applications in aerospace, optics, bearings, ball screws, hydraulics, automotive and precision mould manufacturing.

Features

- Uses a high-precision imported Italian servo turret with faster tool indexing. Turret positioning is achieved by a high-accuracy face-gear coupling with hydraulic clamping, ensuring high positioning accuracy, zero backlash, no wear and low noise.

- The hydrostatic spindle provides <0.2 μm runout and high static stiffness, far exceeding the accuracy of conventional rolling-bearing spindles. The MICRO-T400 achieves roundness ≤0.5 μm and surface roughness Ra ≤0.02 μm, enabling hard turning, precision turning and “turn-instead-of-grind” capability.

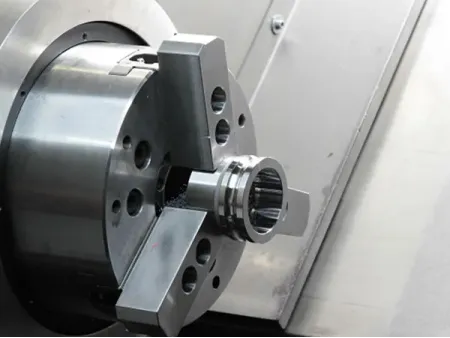

Sample Display

Technical Specifications

| Max. swing over bed (mm) | 400 |

| Max. turning diameter (disc workpieces) (mm) | 300 |

| Max. turning diameter (shaft workpieces) (mm) | 150 |

| Max. turning length (mm) | 320 |

| Max. Workpiece Diameter weight (including fixture) (kg) | 80 |

| Chuck diameter (mm) | 200 (8 inch) |

| Spindle power (kW) | 18.4 |

| Spindle speed range (r/min) | 100–4000 |

| Spindle runout (μm) | < 0.2(0.1) |

| Rated torque (N.m) | 42–47 |

| X-axis travel (mm) | 200 |

| Z-axis travel (mm) | 350 |

| X/Z-axis positioning accuracy (μm) | 3 (optional 1) |

| X/Z-axis repeatability (μm) | 1.5 (optional 0.2) |

| CNC system | FANUC Oi-TF Plus (optional GSK) |