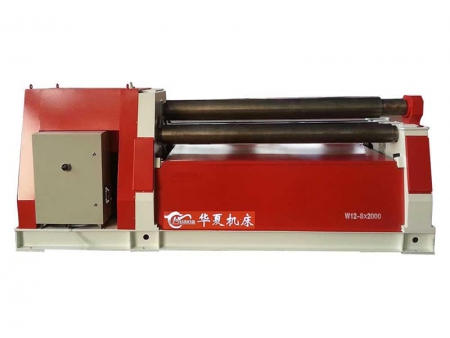

W12 4-roll Plate Rolling Machine, CNC Roll Bender

Request a Quote

The 4 roll plate bending machine is equipped with an NC system, which improves the degree of automation. The bending machine is commonly used in petroleum, chemical industry, boilers, shipbuilding, metal structure and machinery manufacturing industry.

-

Max. Thickness of Plate (mm)

8-40

-

Max. Width of Plate (mm)

2000-3000

-

Rolling Speed (m/min)

4-6.1

-

Thickness of Pre-Bending (mm)

6-36

Parameters

| Model | ||||

| Max. thickness of plate (mm) | 8 | 12 | 25 | 40 |

| Max. width of plate (mm) | 2500 | 2000 | 3000 | 2500 |

| rolling speed (m/min) | 6.1 | 4 | 5 | 4 |

| Thickness of pre-bending (mm) | 6 | 10 | 22 | 36 |

| Min. dia. of plate in full load (mm) | 750 | 850 | 1150 | 1300 |

| Dia. of upper roller (mm) | 300 | 380 | 480 | 560 |

| Dia. Of lower roller (mm) | 280 | 340 | 460 | 520 |

| Dia. Of side roller (mm) | 230 | 280 | 380 | 420 |

| Main power (kW) | 15 | 30 | 55 | 60 |

| Dimension(L)(mm) | 6100 | 7600 | 9000 | 8700 |

| Dimension(W)(mm) | 2000 | 2000 | 3200 | 3500 |

| Dimension(H)(mm) | 2070 | 2150 | 2500 | 2900 |

Features