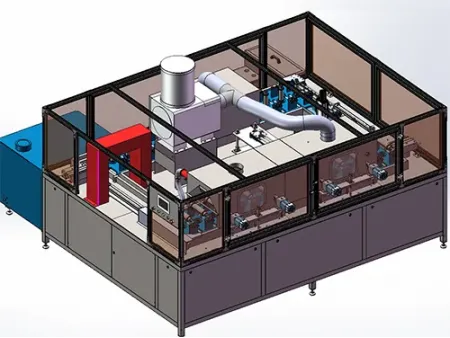

Tunnel Washer for Motor Shafts

Request a Quote

Automatic industrial parts washer machine for efficient washing of mass produced motor shafts

Tunnel washer for motor shafts is built for cleaning motor shafts and similar components. It integrates multiple subsystems to provide intelligent control across the entire process, from conveying and demagnetization to washing and drying, making it well-suited for precision cleaning in motor manufacturing and machining industries.

Cleaning Process

Motor shafts are manually loaded into the system, which automatically initiates the conveyor. Components sequentially undergo spray washing, steam cleaning, cold-air blow-off, and hot-air drying before reaching the unloading platform, where they are manually removed to complete the cycle.

Specifications

| Applicable parts | Motor shaft (diameter 20-150mm, length 500-1500mm) |

| Cleaning efficiency | 5-10min/pc (adjustable depending on the degree of oil contamination) |

| Steam temperature | 150-200℃ |

| Sprinkler pressure | 50-100bar |

| Demagnetization | ≥3000 oersted |

| Drying temperature | 50-80℃ |

| Power supply | 380V/50Hz |

| Total power | 100-180kW (depending on configurations) |

| Water consumption | 200-500L/h (including water for steam) |

| Compressed air | Air pressure 0.6-0.8MPa, Air flow 10-15m³/h |

Key Advantages

- High Efficiency Tunnel washer for motor shafts combines pre-washing, steam cleaning, and drying into one seamless process, cleaning complex parts 2-3 times better than other methods.

- Eco-Friendly Steam heat recycling reduces energy consumption by 40% compared to conventional cleaning.

- Flexible Production Adaptability Quick tooling changes and program switching allow compatibility with diverse motor shaft types, supporting both small-batch customization and mass production.

- Low Operational Costs Durable components (e.g., Italian pumps, Siemens PLCs) ensure ≤0.5 annual failures. Smart diagnostics reduce manual maintenance, cutting total costs by 20% versus comparable equipment.