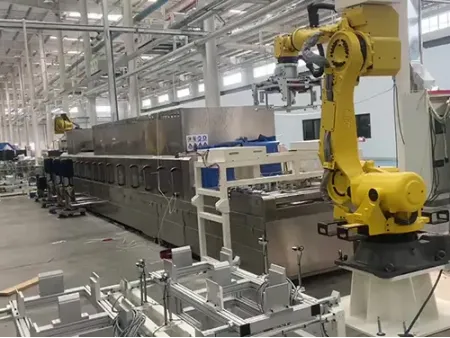

Tunnel Washer for Gears

Request a Quote

Continuous cleaning machine with conveyor belt for thoroughly cleaning large quantities of industrial parts

Tunnel washer for gears is designed to meet the strict cleanliness standards required for modern automotive gears. Since the performance and service life of a vehicle are closely tied to gear quality, any residual oil, machining debris, or dust must be thoroughly removed after processing.

Tunnel washer uses high-temperature, high-pressure steam to clean gear surfaces, efficiently eliminating oil stains, iron chips, and other contaminants, ensuring they consistently meet the required cleanliness levels before final packaging.

Cleaning Process

- Pre-washing

- Steam generation

- Automatic washing

- Rinsing and drying

Specifications

| Machine dimensions | 12700×2420×1920mm |

| Conveying speed | 0.5-2m/min (variable speed control) |

| Cleaning efficiency | 300-400pcs/hour |

| Water consumption | 500L/h |

| Total power | 183kW (full heating), 54kW (no heating) |

| Power supply | 380V±10%, three-phase five-wire, 50Hz |

| Water pressure | 0.3-0.5MPa (tap water) |

| Number of operators | 2 persons |

| Continuous operation | 24 hours continuous running |

Key Advantages

- High Efficiency & Energy Savings Instant steam generator reduces energy consumption; high-temperature, high-pressure steam ensures efficient cleaning, shortening cycle times.

- Eco-Friendly Steam cleaning eliminates the need for chemical detergents, reducing environmental impact; wastewater generated is easy to treat.

- Component Protection Effectively removes stubborn contaminants without scratching gear surfaces.

- Smart Control PLC system with touchscreen interface enables intelligent process control, enhancing operational ease and safety.

- Broad Applicability Suitable not only for new energy vehicle gears but also for cleaning bearings, motor shafts, and parts across industries.