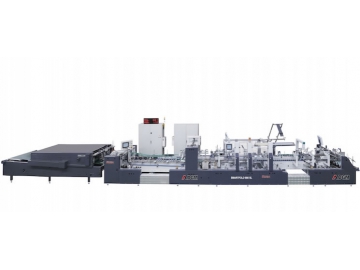

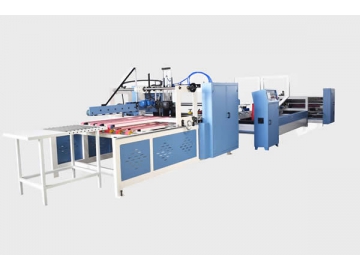

Automatic Carton Folding Gluing Line 800 type Folder Gluer Machine

High Speed Carton Equipment Manufacturer

Description

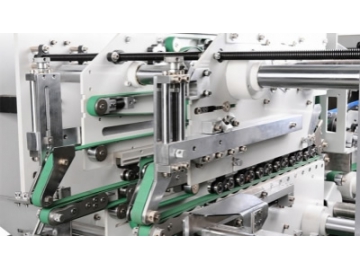

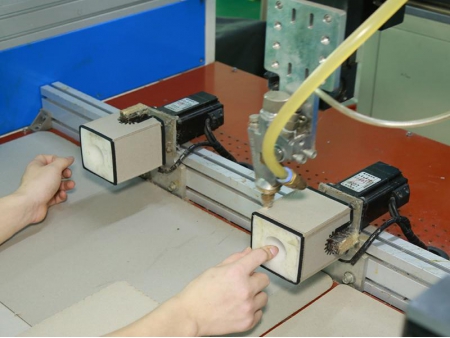

The most advantageous feature in the standard configurations of this folder machine is its on-line inspection device, which is connected to the register table. The carton board is fully registered, then delivered to the inspection section for color-difference detection, overprint deviation detection, die-cutting deviation detection, bar code verification, and other processes. Not only does this ensure the inspection system’s stability, but also reduces labor costs.

This folder-gluer has a maximum speed of 400 m/min and a maximum blank width of 800mm, making it suitable for packaging of carbon boards with a maximum weight of 800 g/m² and corrugated boards of E, F and N types.

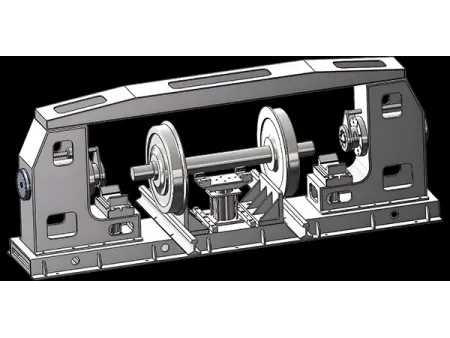

Compared to other folding and gluing systems, this folding carton gluing system is equipped with an electronic back folding system that is controlled and driven using a servo motor. The folding hooks are installed on two independently controlled servo shafts for accurate folding of all box flaps.

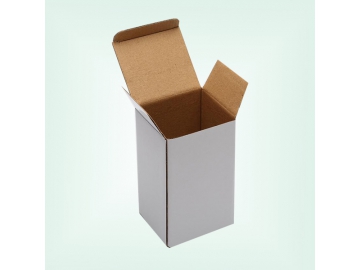

ApplicationThe SMARTVISION 800 – PC is suitable for the production of straight line boxes, crash lock bottom boxes, double wall boxes, and other box types.

The SMARTVISION 800 – SL is used for manufacturing straight-line boxes, crash-lock bottom boxes, double-wall boxes, 4 and 6 corners boxes and other box types.

Produced box type- Straight-line box A: 126 - 800 mm

B: 60 - 800 mm

E: 58 - 380 mm - crash-lock bottom box A: 146 - 800 mm

B: 110 - 800 mm

E: 68 - 368 mm - double-wall box A: 200 - 800 mm

B: 100 - 800 mm

D: 30 - 150 mm

E: 80 - 680 mm - 4-corner box A: 140 - 750 mm

B: 140 - 800 mm

H: 25 - 150 mm - 4-corner box with lid A: 250 - 800 mm

B: 140 - 800 mm

H: 25 - 150 mm - 6-corner box A: 250 - 720 mm

B: 140 - 800 mm

H: 25 - 150 mm

- Carton board

- Corrugated board

Processed materials

| Max. Carton board | 800 g/m² |

| Corrugated flute type | N, E & F |

| Max. speed | 400 m/min |

| Inching speed | 20 m/min |

| Max. Thickness of folded box | 12 mm |

| Max. Blank width | 800 mm |

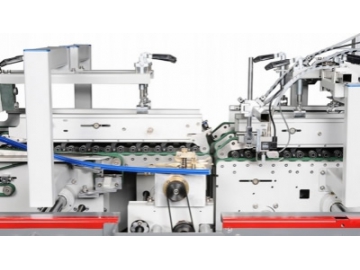

| Total length of pressure conveyor section | 5 m |

| Effective conveying press length | 3.5m |

| Lower belt width | 25mm |

| Outer belt width | 30mm |

| Sheet weight range | 250 - 650 g/m² |

| Inspection size (W x L) | Max. 850 x 650 mm Min. 120 x 120 mm |

| Inspection speed | Max. 250 m/min |

| Item | PC | SL |

| Length | 18.6 m | 18.6 m |

| Width | 1.6 m | 1.6 m |

| Height | 1.9 m | 1.9 m |

| Weight | 10.5 Ton | 11 Ton |

| Item | PC | SL |

| Electrical connected load | 42 kW | 42 kW |

| Compressed air | 6 bar | 6 bar |

| Air compressor capacity | 10 m³/h | 10 m³/h |

| Air tank capacity | 60 L | 60 L |

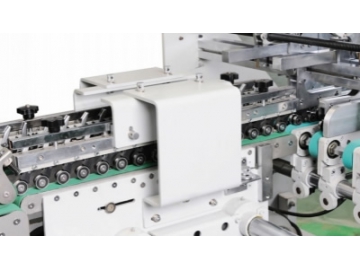

- Feeder section

- Side register table

- Online inspection section

- Pre-folding section

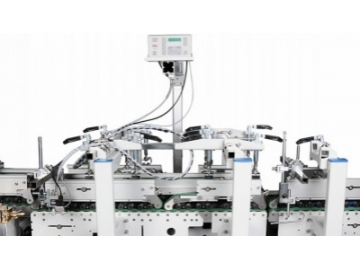

- Crash lock bottom section

- Lower gluing unit

- Folding and closing section

- Trombone section

- Pres section