Your trusted partner for bagging and palletizing systems

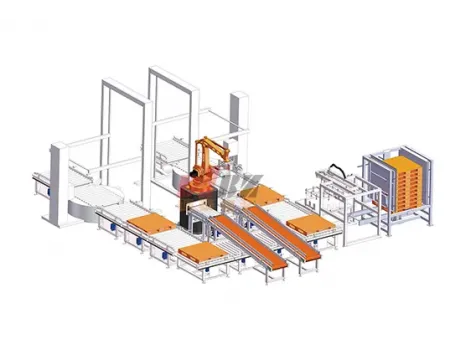

Automated palletizing line using robotic bag palletizer for bag palletizing and handling

Our palletizing line is designed for industrial bag-handling applications and integrates seamlessly with upstream equipment such as automatic bagging machines, weighing units, sewing and sealing stations, and conveying and inspection modules. The entire system operates under coordinated automated control, enabling continuous and stable production with minimal manual involvement.

- Programmable palletizing patterns for different product formats

- Maximum pallet height up to 2300 mm

- Robotic gripper capable of handling up to 1200 bags per hour

- Equipped with full safety guarding for secure and reliable operation

- Multiple gripper designs available to handle bags, cartons, pallets, and slip sheets

- Compatible with robotic brands including KUKA, ABB, FUJI, YASKAWA, and FANUC

Big bag scale for weighing and filling of FIBC big bags with free-flowing granular products

The gravity feed bagging scale is designed for filling large-format FIBC bags, typically ranging from 500 to 2000 kg. It uses the natural flow of free-flowing granular materials for dosing and incorporates load cells for accurate weight measurement. This type of bagging scale is well suited for medium to large production plants or trading operations that manage high-volume material handling.

| Machine dimensions (L×W×H) | 1250×620×1060mm |

| Applicable materials | Flake materials, granular materials, moist materials |

| Weighing range | 20-50kg/bag |

| Capacity | Single scale: 300–500bags/hr Double scale: 800–1200bags/hr (depending on material flowability and bulk density) |

| Accuracy | Static ±0.1% Dynamic ±0.3% (Class X(0.2)) |

| Power supply | AC 220V/380V ±5%, 50 Hz±1%, three-phase four-wire |

| Peak power | 4kW |

| Air supply | 0.5–0.7MPa, 140Nm³/h, inlet pipe diameter 1inch |

| Operating temperature | -5°C to 40°C, dew point -40°C |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

- Building materials: Suitable for cement, fly ash, sand aggregates, and similar bulk materials

- Chemical industry: Used for plastic pellets, fertilizers, industrial salt, and other free-flowing granules

- Mining: Applicable to mineral powders, metal granules, and related materials

- High-capacity production lines: Can be integrated with continuous processes such as fertilizer granulation lines or plastic extrusion lines

- Medium-to-low fluidity materials: Performs well with materials that flow moderately but are not highly cohesive, including phosphate powder and feed pellets