NPK Fertilizer Production Line, High-Tower Granulation (100,000–400,000 t/y)

Complete compound fertilizer production system using tower granulation process for uniform fertilizer granule formation

This fertilizer production line is designed for manufacturing granular compound fertilizers through a high-tower granulation process. Molten urea (or ammonium nitrate melt) is combined with monoammonium phosphate and potassium chloride to form a low-melting eutectic mixture. After reaction and mixing, a free-flowing NPK melt is produced and sprayed into the granulation tower through a rotating differential nozzle.

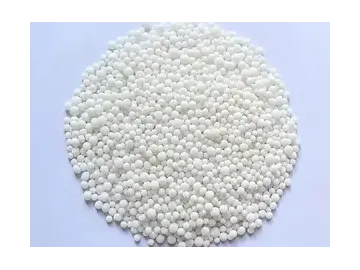

The molten material cools and solidifies in the air, forming granules that are collected at the tower base. The product then passes through further cooling, screening, surface conditioning, weighing, and packaging to produce finished compound fertilizer. Due to differences in density and shrinkage rates of nitrogen, phosphorus, and potassium during cooling, a small shrinkage cavity forms on the granule surface, which is a typical feature of tower-granulated compound fertilizers.

- Production capacity: 100,000–400,000 t/y

- Standard: Complies with GB/T 15063-2020

- Granule size: 2.0–3.5 mm

- Key processes: material melting, slurry preparation, granulation

Batching scale, Urea melting tank, Belt conveyor, Crusher, Bucket elevator, Granulation tower, Cooler, Screening machine, Coating machine, Packaging system, Exhaust gas treatment system

Features- Improved tower structure for efficient operation

- Patented tower-bottom material collector reduces material adhesion at the tower base and lowers overall tower height by 8 to 10 meters.

- Condensate collection channels along the tower wall prevent condensation water from flowing into the tower bottom during high-humidity seasons.

- Flexible material discharge design minimizes particle flattening and breakage, improving finished product yield.

- Innovations in material melting and slurry preparation

- On-tower melting process allows urea or ammonium nitrate to melt directly on the tower, shortening melt residence time and reducing biuret formation.

- Low-temperature melting technology keeps urea melting within 95–110 °C, lowering steam consumption while improving product quality.

- High-efficiency mixing tank combined with slurry filtration and grinding improves slurry fluidity and fineness, prevents nozzle blockage, and enhances granule appearance.

- Efficient granulation and material recycling

- Rotary differential spray nozzles ensure uniform granule formation while reducing wall adhesion and nozzle clogging.

- Automatic off-size particle return system maintains consistent granule quality and improves overall output efficiency.

- Fast granulation system changeover through optimized nozzle preheating and mixer connection enables flexible production switching.

- Environmental protection and energy efficiency

- Low steam consumption: 160–180 kg per ton of fertilizer.

- Low power consumption: 15–20 kWh per ton of fertilizer.

- Environment-friendly conveying equipment effectively controls dust and reduces environmental impact.

- Integrated exhaust gas treatment system ensures emissions meet applicable environmental regulations.

- Cost optimization

- Partial substitution of urea with ammonium chloride reduces or eliminates the need for fillers, lowering compound fertilizer production costs.

- Forced ventilation design reduces tower height by 20 to 30 meters, cutting construction costs and improving production efficiency.