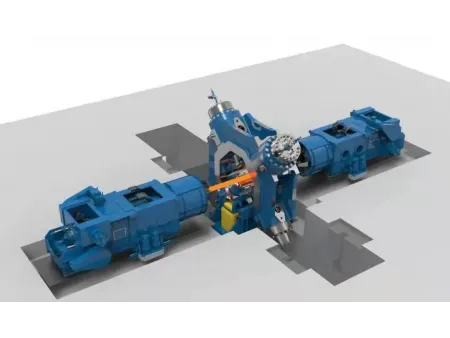

Radial Forging Machine

Request a Quote

Radial forging is a precision forging process where multiple (2-8) hammers are distributed around the billet, performing high-frequency synchronous forging blows along the axis of the forged billet. The billet rotates while axially feeding, causing it to elongate and thin under multi-head helical stretching and deformation.

Applications

Radial forging is suitable for long shaft-type forgings of various shapes, solid or hollow, as well as long, straight hollow shaft forgings with complex internal contours (such as internal threaded holes, internal spline holes, gun barrel rifling, etc.) or very small internal diameters.

How does a CNC radial forging machine differ from a traditional forging press?

How does a CNC radial forging machine differ from a traditional forging press?

A CNC radial forging machine is a high-precision, high-repeatability, and highly automated forging equipment, primarily used for closed-die or semi-closed-die forming of metal billets. It features a high degree of automation, suitable for unmanned production lines.

Does the CNC radial forging machine support multi-station/multi-step forging?

Does the CNC radial forging machine support multi-station/multi-step forging?

The CNC radial forging machine, through modular mold design and intelligent process control, can efficiently support multi-station/multi-step forging, improving the forming efficiency and precision of complex parts.