UF MF Molding Powder Plant (Urea Formaldehyde and Melamine Formaldehyde)

Request a Quote

C15H30N6O6

UF MF molding powder plants provided by Helipont are used in the production of UF (urea formaldehyde resin) and MF (melamine-formaldehyde resin). We supply our clients with the technical design, product design and equipment installation tests.

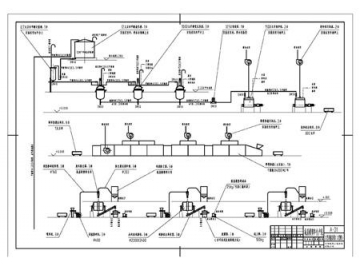

Flow chart

Production Process of UF MF Molding Powder Plant

UF MF molding powder is manufactured via the following two steps:

- Step 1:Reaction→ Kneading→ Drying & Aging

- Step 2:Grinding→ Ball Milling & Post Treatment→ Screening & packing

Annotation: For more information, please do not hesitate to contact us.

Main Equipment

Typical: taking 4000tpa urea-formaldehyde molding powder as an example:

| Equipment & Capacity | Quantity |

| Formalin Overhead Tank of 12CUM (S.S.) | 1 |

| Formalin Measuring tank (S.S.) | 2 |

| Reaction Vessel of 1000 L (Enamel) | 3 |

| Kneader of 1500L (with S.S. Lining) | 2 |

| Kneader cover, companion fan, operation platform | 2 |

| Discharger for Kneader | 6 |

| Mesh-Belt Drying Box | 1 |

| Induced draft device at head of Mesh-belt Drying Box | 1 |

| Discharger for Mesh-belt Drying Box | 5 |

| Particle Skip | 8 |

| Lifter | 2 |

| Feeder | 3 |

| High Speed Eddy Current Grinder and companion tubes | 3 |

| Dedust & Discharge Unit | 3 |

| Ball Milling Machine with Water Jacket, Powder Discharge Cone | 3 |

| Porcelain lining for Ball Milling Machine | 3sets |

| Spiral Conveyor | 3 |

| Screener | 3 |

| Steam Drum within Workshop | 1 |

| Electrical Box, Operation Box & Lighting Cables | Full set |

| Pipes, Pipe Fittings, Anti-Corrosion and Painting within battery limit | |

Specification of Raw Material and Utilities:

| Material / Utility | Value |

| Formaldehyde | 37%-52% |

| Urea | 46.5% |

| Melamine | 99.8% |

| α-cellulose(wood pulp) | Min 90% |

| hexamine | 99.3% |

| Zinc stearate(zinc content) | 10.3%-11.3% |

| Latent curing agent | |

| Mill base (include: titanium dioxide, pigment) | |

| Cooling water (required for cooling, intermittent supply) | 31℃ |

| 0.3Mpa | |

| Low pressure steam | 0.6Mpa |

| Instrument air | 0.4Mpa |

Product Quality

| Item | Index |

| Color | |

| Fluidity/ mm | 140~200 |

| Moisture/% | 0.04 |

| Dielectric strength/ (mV.m-1) | 9 |

| Notch impact strength/ ( kJ.m-2 ) | 1.8~1.7 |

| Bending strength/MPa | 85~75 |

| Molding shrinkage/% | 0.6~1.0 |

| Tracking index/V |

Consumption Quota

| Particular | Unit consumption |

| Formaldehyde | 960kg |

| Urea | 470kg |

| Wood pulp | 260kg |

| Hexamine | 43kg |

| Zinc stearate | 6kg |

| Mill base | Depending |

| packing | 41set |