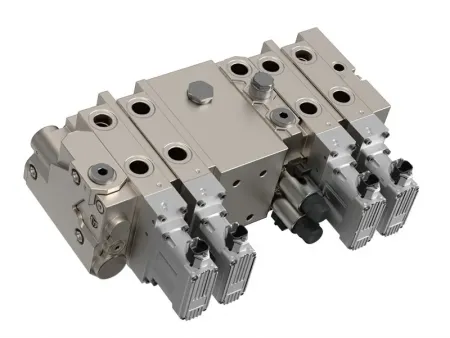

Load-Sensing Control Block

Request a Quote

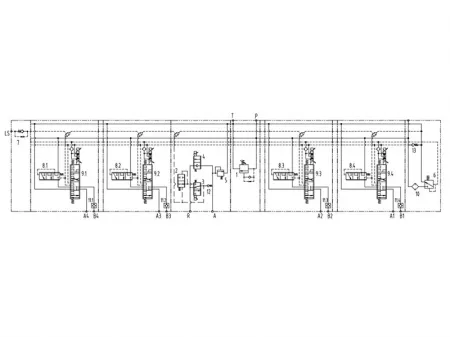

The load-sensing control block uses electro-proportional signals to accurately adjust spool opening, allowing precise control of output flow at the working ports, with capacities up to 120 L/min. This enables the hydraulic system to efficiently meet the demands of different operating conditions, improving overall machine performance and efficiency.

Features

- Accurate flow distribution and coordinated actuation, ensuring smooth multi-function operation

- Energy-saving design to reduce power consumption and improve system efficiency

- Integrated intelligent safety protection, enhancing operational reliability and equipment protection

Specifications

| Max. Operating Pressure | 350bar |

| Rated Flow | 120L/min |

| Fluid Temperature Range | -40℃~100℃ |

| Ambient Temperature Range | -40℃~80℃ |

| Surface Treatment | Nickel plated |

| Oil Viscosity Range | ISO 20~400mm²/s |

Applications

The load-sensing control block is ideal for combine harvesters, precision seeders, tractors, and smart irrigation systems, addressing common limitations of traditional valves with advanced CAN bus load-sensing solutions:

| Applications | Issues with Traditional Valve | CAN Bus Load-Sensing Solution | ||

| Combine harvester | Header lifting is unstable, causing high crop loss rates | Electro-proportional fine adjustment with pressure compensation keeps header height steady | ||

| Precision seeder | Inconsistent seeding depth leads to uneven germination | Closed-loop hydraulic cylinder pressure control ensures uniform downforce across all planting rows | ||

| Large tractor hitch system | Power is unevenly distributed when operating multiple implements simultaneously | CAN bus coordination manages multi-valve flow, synchronizing deep tillage plows and fertilizer spreaders | ||

| Smart irrigation equipment |

| Using GIS data and CAN bus signals, valve opening is automatically adjusted for optimized irrigation |