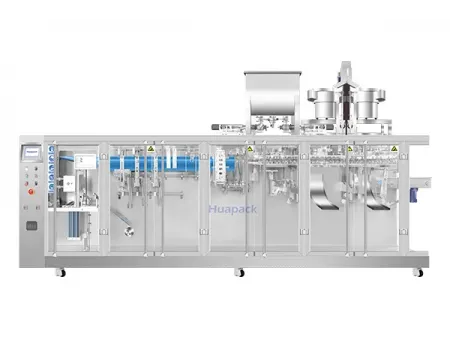

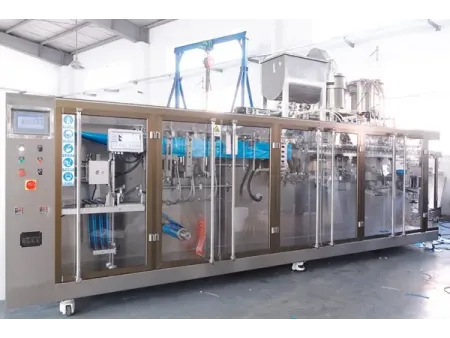

Spouted Pouch HFFS Packaging Machine, 2-Nozzle Filling

Horizontal form fill seal machine

These dual-nozzle rollstock spouted pouch machines are built for higher output, delivering about twice the capacity of single-nozzle models, with a theoretical speed of up to 120 pouches per minute and around 100 pouches per minute in real production. They are ideal to pack products such as snack granules, pet food, powdered drinks, or detergent, especially when a tight seal and easy pouring through the spout are part of the product’s everyday use.

| Rollstock spouted pouch parameters | | | | |

| Pouch parameters | Min. pouch size | 70x90mm | 70x120mm | 90x140mm |

| Max. pouch size | 120x225mm | 140x250mm | 160x300mm | |

| Filling volume | 150ml | 200ml | 400ml | |

| Packaging speed | ≤120 | ≤100 | ≤90 | |

| Rollstock film thickness | 70-150u | 70-150u | 70-150u | |

| Max. rollstock film outer diameter | 500mm | 500mm | 500mm | |

| Machine specifications | Rollstock film core inner diameter | 70-80mm | 70-80mm | 70-80mm |

| Machine dimensions (L × W × H) | 5200x970x1460 | 6500x970x1460 | 7200x970x1460 | |

| Machine weight | 2100kg | 2200kg | 2300kg | |

| Operating conditions | Operating temperature | ﹣10℃- 50℃ | ﹣10℃- 50℃ | ﹣10℃- 50℃ |

| Operating humidity | Less than 85% | Less than 85% | Less than 85% | |

| Power supply | AC380V, 50HZ | AC380V, 50HZ | AC380V, 50HZ | |

| Air pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Air consumption | 300L/min | 300L/min | 300L/min | |

| Main drive power | 5.5kw | 5.5kw | 5.5kw | |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

Based in Shanxi, a pharmaceutical company purchased our rollstock spouted pouch packaging machine in 2025 and later placed additional orders. The pouch packaging equipment has shown stable performance in daily operation, and the positive feedback from their team reflects their satisfaction and continued trust in our pouch packaging solutions.