Air-cooled Inverter Scroll Chiller

- Cooling capacity: 3~200kW

- Compressor type: Inverter scroll

- Flow Rate: 4~48 m³/h

Anges air-cooled inverter scroll chiller was designed for industrial applications where reliable cooling is critical for stable operation.

The air-cooled chiller utilizes variable frequency drive to greatly improve energy efficiency, it saves over 20% of energy use while keeping equipment in optimal operating condition.

Our inverter scroll chillers are offered with cooling capacity ranging from 3kW to 200kW to accommodate various cooling needs. We are able to supply appropriate industrial chiller that is made precisely to your specific applications.

Cooling capacity: 3.54 kW~12.74kW

Total input power: 2.09kW~4.59kW

Compressor type: Inverter scroll

Standard flow rate: 4m³/h

Evaporator: Shell and tube

Cooling capacity: 7.85 kW~28.30kW

Total input power: 4.57kW~10.16kW

Compressor type: Inverter scroll

Standard flow rate: 11.4m³/h

Evaporator: Shell and tube

Cooling capacity: 12.05 kW~ 43.38kW

Total input power: 5.98kW~14.75kW

Compressor type: Inverter scroll

Standard flow rate: 12.5m³/h

Evaporator: Shell and tube

Cooling capacity: 15.70kW~56.60kW

Total input power: 8.06kW~19.24kW

Compressor type: Inverter scroll

Standard flow rate: 25m³/h

Evaporator:Shell and tube

Cooling capacity: 18.76kW~67.60kW

Total input power: 8.94kW~22.42kW

Compressor type: Inverter scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 23.55kW~84.90kW

Total input power: 12.29kW~29.07kW

Compressor type: Inverter scroll

Standard flow rate: 25m³/h

Evaporator:Shell and tube

Cooling capacity: 31.40kW~113.20kW

Total input power: 5.40kW~37.77kW

Compressor type: Inverter scroll

Standard flow rate: 48m³/h

Evaporator:Shell and tube

Cooling capacity: 37.52kW~135.20kW

Total input power: 17.49kW~44.44kW

Compressor type: Inverter scroll

Standard flow rate: 48m³/h

Evaporator:Shell and tube

| Model | Cooling capacity | Total input power | Compressor type | Standard flow rate | Evaporator | ||

| Low frequency | High frequency | Low frequency | High frequency | ||||

ACKV-5 | 3.54 kW | 12.74kW | 2.09kW | 4.59kW | Inverter | 4m³/h | Shell and tube |

ACKV-10 | 7.85 kW | 28.30kW | 4.57kW | 10.16kW | Inverter | 11.4m³/h | Shell and tube |

ACKV-15(D) | 12.05 kW | 43.38kW | 5.98kW | 14.75kW | Inverter | 12.5m³/h | Shell and tube |

ACKV-20(D) | 15.70kW | 56.60kW | 8.06kW | 19.24kW | Inverter | 25m³/h | Shell and tube |

ACKV-25(D) | 18.76kW | 67.60kW | 8.94kW | 22.42kW | Inverter | 25m³/h | Shell and tube |

ACKV-30(T) | 23.55kW | 84.90kW | 12.29kW | 29.07kW | Inverter | 25m³/h | Shell and tube |

ACKV-40(F) | 31.40kW | 113.20kW | 15.40kW | 37.77kW | Inverter | 48m8/h | Shell and tube |

ACKV-50(F) | 37.52kW | 135.20kW | 17.49kW | 44.44kW | Inverter | 48m8/h | Shell and tube |

* Please download for details.

- No need to start & stop compressor frequently, providing stable running status, precise temperature control, lower sound level and prolonged service life;

- Minimal starting current of drive motor enables the impact on the power grid to be greatly decreased;

- PLC control, touch screen and user-friendly HMI interface, easy to operate;

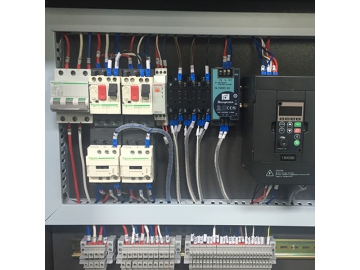

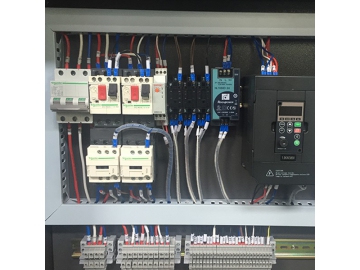

- Adopting world's well-known compressors, such as Danfoss, Copeland and Panasonic, and our main electrical components are from Schneider;

- Copper tube and aluminum fin condenser with external rotor type fan, resulting in high efficiency and low sound levels;

- Shell & tube evaporator is used as standard configuration, featuring high efficiency, excellent energy saving and reliable stability; Other evaporators are also available as per your request, like stainless steel plate evaporator;

- Eco-friendly refrigerant R410A is used for improved cooling performance without harming the ozone layer;

- Built-in water pump and water tank (optional) can be easily installed and directly put into use by simply connecting water pipes and power supply;

- Designed with multiple protection functions, such as phase failure protection, flow protection, high/low pressure protection, overheat protection, providing high reliability, low failure rate and excellent performance;

- Stainless steel plate evaporator

- Common water pump or 4-8bar high pressure pump

- Water tank

- Low noise option