Air-cooled Scroll Chiller

- Cooling capacity: 6-184.85kW

- Compressor type: Scroll

- Flow Rate: 4~48 m³/h

Anges offers air-cooled scroll chiller with cooling capacities ranging between 14kW and 146kW, the chilled water temperature provided is within a range of 5℃-30℃. These scroll chillers are featured by stable operation, high efficiency and energy saving, which are ideal solution for process cooling applications in data centers, buildings and medical facilities.

We are able to supply appropriate industrial chiller that is made precisely to your specific applications.

Cooling capacity: 14.5kW

Total input power: 5.53kW

Compressor type: Scroll

Standard flow rate:4m³/h

Evaporator: Shell and tube

Cooling capacity: 29kW

Total input power: 11.22kW

Compressor type: Scroll

Standard flow rate: 11.4m³/h

Evaporator: Shell and tube

Cooling capacity: 46.2kW

Total input power: 15.06kW

Compressor type: Scroll

Standard flow rate: 12.5m³/h

Evaporator: Shell and tube

Cooling capacity: 60.2kW

Total input power: 19.96kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 73.2kW

Total input power: 22.36kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 92.4kW

Total input power: 28.96kW

Compressor type: Scroll

Standard flow rate: 25m³/h

Evaporator: Shell and tube

Cooling capacity: 120.4kW

Total input power: 39.2kW

Compressor type: Scroll

Standard flow rate: 48m³/h

Evaporator: Shell and tube

Cooling capacity: 146.4kW

Total input power: 43.92kW

Compressor type: Scroll

Standard flow rate: 48m³/h

Evaporator: Shell and tube

| Model | Cooling capacity | Total input power | Compressor type | Standard flow rate | Evaporator |

ACK-5 | 14.5kW | 5.53kW | Scroll | 4m³/h | Shell and tube |

ACK-10(D) | 29kW | 11.22kW | Scroll | 11.4m³/h | Shell and tube |

ACK-15 | 46.2kW | 15.06kW | Scroll | 12.5m³/h | Shell and tube |

ACK-20(D) | 60.2kW | 19.96kW | Scroll | 25m³/h | Shell and tube |

ACK-25(D) | 73.2kW | 22.36kW | Scroll | 25m³/h | Shell and tube |

ACK-30(D) | 92.4kW | 28.96kW | Scroll | 25m³/h | Shell and tube |

ACK-40(F) | 120.4kW | 39.2kW | Scroll | 48m8/h | Shell and tube |

ACK-50(F) | 146.4kW | 43.92kW | Scroll | 48m8/h | Shell and tube |

* Please download for details.

- Refrigerant R22, R407C, R410A, R134A are optional;

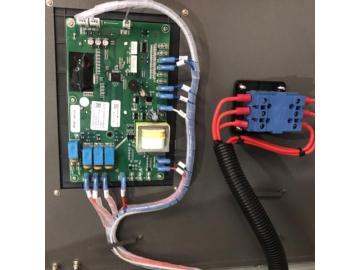

- Microcomputer control with user-friendly HMI interface, easy to operate; Siemens PLC control is optionally configurable as per customer's request;

- Adopting world's well-known compressors, such as Danfoss, Copeland and Panasonic, and our main electrical components are from Schneider;

- Copper tube and aluminum fin condenser with external rotor type fan, resulting in high efficiency and low sound levels;

- Shell & tube evaporator is used as standard configuration, featuring high efficiency, excellent energy saving and reliable stability; Other evaporators are also available as per your request, like stainless steel plate evaporator;

- Built-in water pump and water tank (optional) can be easily installed and directly put into use by simply connecting water pipes and power supply;

- Designed with multiple protection functions, such as phase failure protection, flow protection, high/low pressure protection, overheat protection, providing high reliability, low failure rate and excellent performance;

- Stainless steel plate evaporator

- Common water pump or 4-8bar high pressure pump

- Water tank

- Low noise option

Rubber and Plastic

In rubber and plastic industry, precision temperature control is an essential factor for improving product quality and production efficiency. Injection molding is one of the most effective method to produce rubber and plastic parts. It requires heat to convert the plastic particles into molten status for injection into the mold where plastic parts cool down. The industrial chillers can perfectly reduce the cooling time and ensure the quality of plastic parts.

Electroplating

During electroplating process, industrial chillers are commonly used to remove the heat generated and keep the process in a constant temperature range, making the metal molecules quickly attach to the surface of the plated parts with a stable current, while increasing the smoothness and density of the plated parts.

Pharmaceutical

A chiller plays a vital role in controlling of temperature and humidity in pharmaceutical industry, it can efficiently remove the heat in active pharmaceutical ingredient (API) production process.