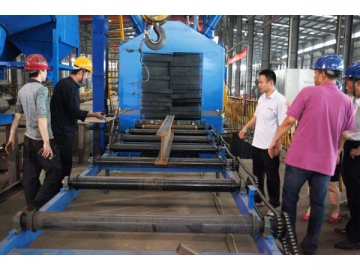

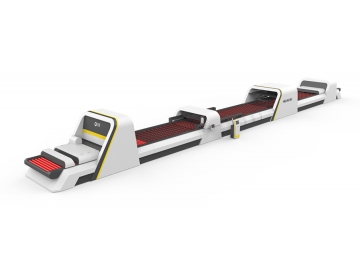

Roller Conveyor Shot Blast Machine for H Shaped Steel

The roller conveyor shot blast machine for H shaped steel is intended to remove rust and mill scale from surfaces of different kinds of steel plates, and it boasts high degree of automation because it loads and unloads work pieces in an automatic way, meeting the requirements of automatic production line. So, it has been extensively utilized to make ships, automobiles, locomotives, bridges and construction machines. In addition, this abrasive blasting machine could also eliminate stress.

System ConfigurationOur roller conveyor shot blast machine is mainly comprised of the following parts.

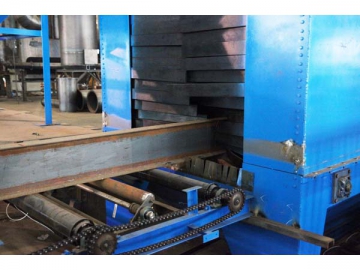

1. Blast Cabinet, Pre-Blastroom and Post-BlastroomThe blast cabinet, pre-blastroom and post-blastroom are all made from steel plates and steel profiles through welding process, and they are lined with high chromium steel plates which are fixed by protective nuts. There is an access door for the pre-blastroom and post-blastroom, respectively.

2. Blast Wheel AssemblyComposed of blast wheel, turbine, belt pulley, V-belt and bed plate, the blast wheel assemblies are installed on the side walls of blast cabinet, and there are 6 of them in total. Their position and angle are calculated by 3D dynamic simulation to offer full surface cleaning with minimized dead zone. When it comes to our roller conveyor shot blast machine, Q034 blast wheel is used, and it is a highly efficient product manufactured using the latest technology.

3. Abrasive Reclamation SystemThe abrasive reclamation system includes screw conveyor, bucket elevator, sand separator, pneumatic valve, abrasive delivery chute, etc.

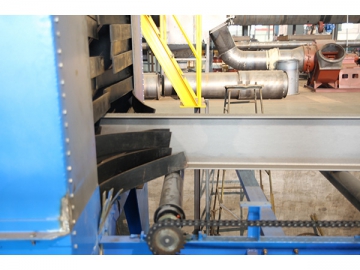

4. Cleaning System

After derusting, there are remaining abrasives on the surface of steel plates, and this cleaning system is designed to make use of both brushing and blowing to remove these abrasives.

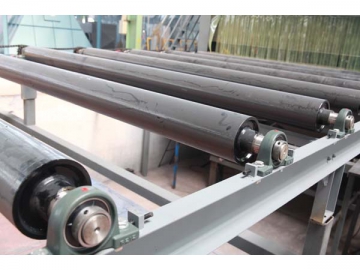

As indicated by its name, our roller conveyor shot blast machine uses roller conveyor to transport steel plates, and this system consists of in-feed roller, pre-blastroom roller, blast cabinet roller, post-blastroom roller and out-feed roller.

6. Dust Removal SystemOur wheel blasting machine is equipped with a two stage dust removal system, and this system covers dust collector, blower, settling box, pipeline, etc.

7. Electrical Control System

Our roller conveyor shot blast machine adopts Siemens PLC controller and frequency converter, while other electrical devices are genuine CHINT products. Moreover, there is a switch used to change between automatic mode and manual mode, and its inter-locking and self-locking functions help this metal surface cleaning equipment to work in a safe and reliable way.

8. Pneumatic Control System

The pneumatic control system is formed by gas source handling components and pneumatic executive components.

Ordering Information

The roller conveyor shot blast machine can be tailored in max. work piece size, number of blast wheel, number of work station, size of blast cabinet and other parameters to better fit customer’s requirements.

| Item | Unit | | | | |

| Effective cleaning width | mm | 800 | 1200 | 1500 | 1800 |

| Feed port size of blast cabinet | mm | 1000×1500 | 1400×1700 | 1700×1700 | 2000×1800 |

| Work piece length | mm | 1200-12000 | 1200-13000 | 1500-13000 | 2000-13000 |

| Work piece size | mm | 800×1200 | 1200×1500 | 1500×1500 | 1800×1600 |

| Speed of roller conveyor (stepless) | m/min | 0.5-4 | 0.5-4 | 0.5-4 | 0.5-4 |

| Abrasive consumption | kg/min | 8×125 | 8×180 | 8×180 | 8×250 |

| Initial abrasive quantity | kg | 4000 | 5000 | 5000 | 6000 |

| Air requirement | m3/h | 20000 | 220000 | 25000 | 25000 |

| Total power (without dust removal system) | kW | 90 | 130 | 180 | 180 |