Water-Cooled Centrifugal Chiller

Chilled water system for commercial applications

The H.Stars 50STD centrifugal water-cooled chiller is designed to be energy-efficient, using a secondary centrifugal compressor and self-developed and produced high-efficiency spray evaporator with R134a refrigerant. This model boasts an impressive 6.3 EER and a cooling capacity range of 2000kW to 10000kW, with chilled water outlet temperature of 5°C to 20°C. Its four available voltage systems are 380V, 6kV, 6.6kV and 10kV, with tailor-made, non-standard units achievable upon request. H.Stars also produce high-voltage, seawater and other power supply models upon request.

- This two-stage centrifugal compressor has the advantage of being unlikely to surge, as it is powered by a system economizer to help with interstage supplementation. This technology boosts cooling capacity by at least 10%.

- Evaluate the potential surge area accurately and adjust the rotate speed and IGV quickly to prevent instability and make operation more safe.

- By incorporating a gear speed increase drive, the impeller volume is reduced while the motor starting torque is reduced, minimizing the downtime.

- The motor and compressor are seamlessly connected, allowing operation to be quiet, while avoiding any risk of spillage.

- The motor's cooling system utilizes liquid refrigerant, significantly reducing the operating temperature while efficiently increasing efficiency.

- High-strength ball bearing or roller bearings for the compressor, preventing unexpected shutdown.

- Self-designed spray heat exchanger technology capitalizing on the enhanced efficiency of production. Precise liquid level control guarantees that the evaporator is at an optimal state of heat exchange at all times.

- The condenser is equipped with droplet separation technology to guarantee a high level of efficiency and complete heat exchange across the condensing heat exchanger tube. This results in a impressive COP value of 6.3.

- Our patented heat recovery technology ensures the heat generated during the refrigeration process is captured and recycled. Get chilled water and hot water at no cost!

- A perfect oil circuit system, with its independent oil return system, guarantees that oil is promptly returned to the injection pump regardless of the operating conditions.

- This unit features a built-in oil cooler, cooled by a safe and dependable refrigerant, guaranteeing reliability.

- The oil pump is designed and placed within the compressor oil sump, removing any possibility of the pump leaking.

- The latest microcomputer-controlled touch interface makes monitoring operating data effortless and quick, eliminating the need for constant oversight. Constant feedback on maintenance can be obtained in real-time, which helps ensure the smooth operation of the unit. Additionally, it can be linked to the user's centralized control system, giving the user a comprehensive understanding of the machine's conditions at any time.

- This specially-engineered multi-stage throttling device features an self-adaptive capability, enabling it to perfect adjust the refrigerant supply when the load or conditions shift - free from lag, ensuring optimum efficiency of the unit in any situation.

Water-Cooled Centrifugal Chiller

Refrigerant: R134a

Power supply: 380V-3N-50Hz

| Model | Nominal cooling capacity | Power input kW | Capacity control % | Refrigerant charge kg | Condenser | Evaporator | Noise level dB(A) | Shipping weight kg | Operating weight kg | |||||||

| kW | USRT | Pipe diameter (inlet/outlet) in | Water flow m3/h | Design water pressure MPa | Water pressure drop kPa | Pipe diameter (inlet/outlet) in | Water flow m3/h | Design water pressure MPa | Water pressure drop kPa | |||||||

| | 1740 | 495 | 283 | 25%~100% | 500 | 6" | 348 | 1 | 66 | 6" | 299 | 1 | 60 | 80 | 10000 | 10500 |

| | 1914 | 544 | 312 | 550 | 6" | 383 | 1 | 66 | 6" | 329 | 1 | 60 | 81 | 11000 | 11500 | |

| | 2088 | 594 | 340 | 600 | 8″ | 418 | 1 | 74 | 8″ | 359 | 1 | 74 | 82 | 12000 | 12500 | |

| | 2262 | 643 | 368 | 650 | 8″ | 452 | 1 | 74 | 8″ | 389 | 1 | 74 | 83 | 12500 | 13000 | |

| | 2320 | 660 | 385 | 700 | 10″ | 465 | 1 | 74 | 10″ | 399 | 1 | 74 | 84 | 13000 | 13500 | |

| | 2785 | 792 | 448 | 800 | 10″ | 556 | 1 | 76 | 10″ | 479 | 1 | 76 | 85 | 14000 | 14500 | |

| | 3200 | 910 | 525 | 900 | 12″ | 641 | 1 | 78 | 12″ | 550 | 1 | 78 | 86 | 15000 | 15500 | |

| | 3550 | 1009 | 582 | 1000 | 12″ | 711 | 1 | 80 | 12″ | 610 | 1 | 80 | 87 | 16000 | 16500 | |

| | 3828 | 1088 | 623 | 1100 | 12″ | 765 | 1 | 80 | 12″ | 658 | 1 | 80 | 87 | 17000 | 17500 | |

| | 4175 | 1187 | 672 | 1200 | 12″ | 834 | 1 | 82 | 12″ | 718 | 1 | 82 | 88 | 18000 | 18500 | |

| | 4570 | 1299 | 732 | 1300 | 14″ | 912 | 1 | 82 | 14″ | 786 | 1 | 82 | 89 | 19000 | 19500 | |

| | 4777 | 1358 | 769 | 1400 | 14″ | 954 | 1 | 84 | 14″ | 821 | 1 | 84 | 90 | 20000 | 20500 | |

| | 5220 | 1484 | 850 | 1500 | 14″ | 1044 | 1 | 84 | 14″ | 898 | 1 | 84 | 90 | 21000 | 21500 | |

| | 5568 | 1583 | 906 | 1600 | 14″ | 1113 | 1 | 84 | 14″ | 958 | 1 | 84 | 90 | 23000 | 23500 | |

| | 5916 | 1682 | 963 | 1700 | 14″ | 1183 | 1 | 84 | 14″ | 1017 | 1 | 84 | 91 | 25000 | 25500 | |

| | 6264 | 1781 | 1020 | 1800 | 14″ | 1253 | 1 | 84 | 14″ | 1077 | 1 | 84 | 91 | 27000 | 27500 | |

| | 6612 | 1880 | 1076 | 1900 | 16″ | 1322 | 1 | 84 | 16″ | 1137 | 1 | 84 | 91 | 29000 | 29500 | |

| | 7100 | 2019 | 1164 | 2000 | 16″ | 1421 | 1 | 84 | 16″ | 1221 | 1 | 84 | 92 | 30000 | 30500 | |

| | 7308 | 2078 | 1190 | 2100 | 16″ | 1461 | 1 | 84 | 16″ | 1257 | 1 | 84 | 92 | 31000 | 31500 | |

| | 7656 | 2177 | 1246 | 2200 | 16″ | 1531 | 1 | 84 | 16″ | 1317 | 1 | 84 | 92 | 32000 | 32500 | |

| | 8004 | 2276 | 1303 | 2300 | 16″ | 1601 | 1 | 84 | 16″ | 1376 | 1 | 84 | 92 | 33000 | 33500 | |

| | 8352 | 2375 | 1360 | 2400 | 16″ | 1670 | 1 | 84 | 16″ | 1436 | 1 | 84 | 93 | 34000 | 34500 | |

| | 8700 | 2474 | 1416 | 2500 | 18″ | 1740 | 1 | 84 | 18″ | 1496 | 1 | 84 | 93 | 35000 | 35500 | |

| | 9048 | 2573 | 1473 | 2600 | 18″ | 1809 | 1 | 84 | 18″ | 1556 | 1 | 84 | 93 | 36000 | 36500 | |

| | 9396 | 2672 | 1530 | 2700 | 18″ | 1879 | 1 | 84 | 18″ | 1616 | 1 | 84 | 93 | 37000 | 37500 | |

| | 9554 | 2717 | 1538 | 2800 | 18″ | 1907 | 1 | 84 | 18″ | 1643 | 1 | 84 | 94 | 38000 | 38500 | |

| | 10092 | 2869 | 1643 | 2900 | 18″ | 2018 | 1 | 84 | 18″ | 1736 | 1 | 84 | 94 | 39000 | 39500 | |

| | 10440 | 2968 | 1700 | 3000 | 18″ | 2088 | 1 | 84 | 18″ | 1795 | 1 | 84 | 94 | 40000 | 40500 | |

Notes:

- 1. Rated cooling capacity standard: evaporator water inlet/outlet temperature 12℃/7℃, condenser water inlet/outlet temperature 30℃/35℃, fouling factor 0.088m²•℃/kW;

- 2. Chiller water temperature range: 5℃~20℃;

- 3. Cooling water temperature range: 15℃~40℃;

- 4. Specifications and dimensions are subject to improvement without notice.

Variable frequency centrifuge unit

The variable frequency centrifuge unit is a modern unit which incorporates both a frequency converter and existing unit operations in order to achieve frequency conversion. With this upgrade, its energy efficiency is drastically improved at partial loads, making it a truly transformative double efficient unit capable of reaching full load efficiency (COP) as well as a intergrated part-load value (IPLV).

Heat recovery

The chiller's condensing heat, typically released into the atmosphere via a cooling tower, can now be effectively harnessed. With the heat recovery technology, heat absorbed during cooling can be transferred to the building, providing hot water where needed. During the cooling season, the heat recovery unit can provide free hot water above 50°C, utilizing up to 30-100% of the cooling capacity for heat recovery.

Heat exchanger tubes

Cloud service (remote control)

It offers the ability to manage operations without the need to be on-site, providing a convenient and efficient way to complete tasks.

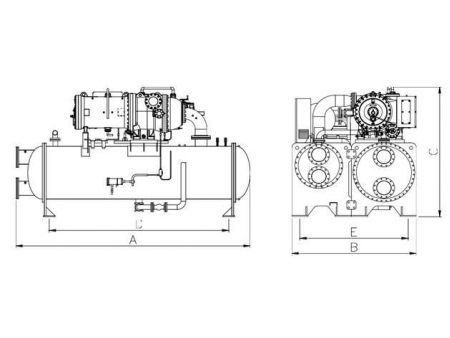

| Model | A | B | C | D | E |

| | 4100 | 2400 | 2500 | 3100 | 1800 |

| | 4100 | 2400 | 2500 | 3100 | 1800 |

| | 4600 | 2550 | 2900 | 3400 | 2000 |

| | 4600 | 2550 | 2900 | 3400 | 2000 |

| | 4600 | 2550 | 2900 | 3400 | 2000 |

| | 4800 | 2800 | 2950 | 3400 | 2300 |

| | 4800 | 2800 | 2950 | 3400 | 2300 |

| | 4800 | 2800 | 2950 | 3400 | 2300 |

| | 5000 | 2800 | 2950 | 6800 | 2300 |

| | 4200 | 2500 | 2500 | 3200 | 1800 |

| | 4350 | 2550 | 2600 | 3250 | 1800 |

| | 4500 | 2600 | 2800 | 3300 | 1900 |

| | 4600 | 2650 | 2900 | 3400 | 2000 |

| | 4800 | 2700 | 2900 | 3400 | 2100 |

| | 4950 | 1750 | 2950 | 3400 | 2200 |

| | 5500 | 2800 | 2950 | 3400 | 2300 |

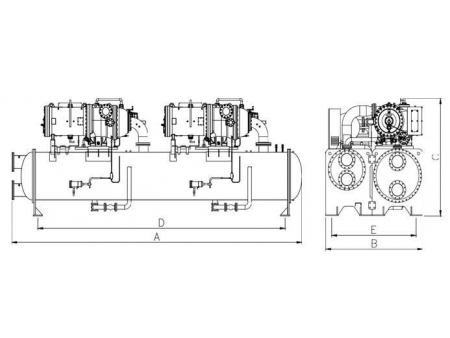

Double Compressor

| Model | A | B | C | D | E |

| | 6000 | 2800 | 2950 | 6800 | 2300 |

| | 6000 | 2800 | 2950 | 6800 | 2300 |

| | 7000 | 2800 | 2950 | 6800 | 2300 |

| | 8000 | 2800 | 2950 | 6800 | 2300 |

| | 9000 | 2800 | 2950 | 6800 | 2300 |

| | 9500 | 2800 | 2950 | 6800 | 2300 |

| | 9600 | 2800 | 2950 | 6800 | 2300 |

| | 9700 | 2800 | 2950 | 6800 | 2300 |

| | 9700 | 2800 | 2950 | 6800 | 2300 |

| | 9700 | 2800 | 2950 | 6800 | 2300 |

| | 9750 | 2800 | 2950 | 6800 | 2300 |

| | 9800 | 2800 | 2950 | 6800 | 2300 |

| | 9900 | 2800 | 2950 | 6800 | 2300 |

| | 10000 | 2800 | 2950 | 6800 | 2300 |

| | 10000 | 2800 | 2950 | 6800 | 2300 |

| | 10000 | 2800 | 2950 | 6800 | 2300 |

| | 9000 | 2800 | 2950 | 6800 | 2300 |