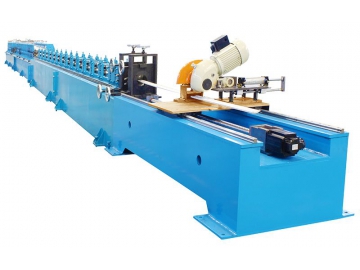

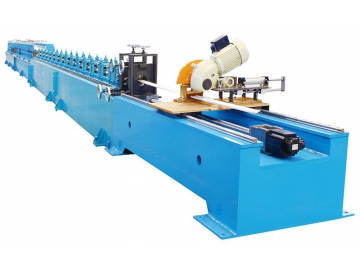

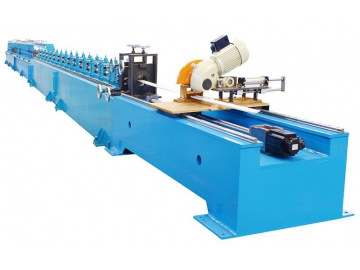

39/42/55 Roller Shutter Slat Roll Forming Line

Roll forming machine for double skin roller shutter door with PU foam insulated

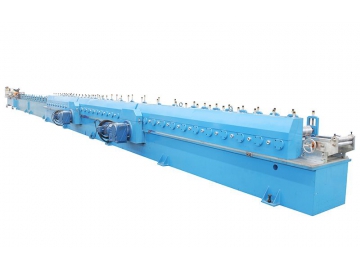

The 39/42/55 roller shutter slat roll forming line is an insulated roller shutter door production line consisting of uncoiler, roll forming machine, PU foaming machine and cutting machine. This roller shutter slat production line conducts the entire process from the raw material to the finished product ready for installation, significantly improving production efficiency while lowering labor cost.

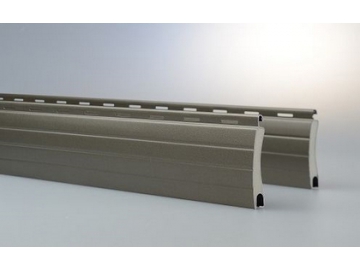

The produced product is roller shutter slat comprising coated steel sheet (or aluminum sheet) filled with polyurethane foam insulation, it can be widely used as industrial rolling doors in a huge variety of sectors such as food, electronic, textile, printing, packaging, cold room, automotive, chemical, pharmaceutical, logistics, shopping mall, storage and warehouse.

Samples of Finished Product

- Uncoiler (2 tons)

- Roll forming machine

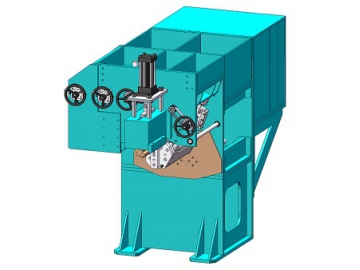

- Low pressure PU foaming machine (SAIP Italy or China Brand)

- Fly saw cutting system with servo motor

- Mechanical punching system

- PLC automatic control system

- Runout table

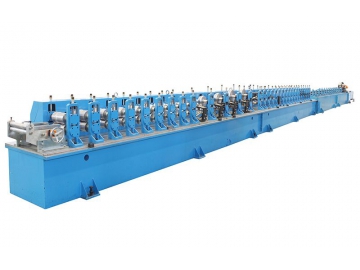

- Applicable material: aluminum sheet/steel sheet

- Coil thickness: 0.28-0.35mm

- Coil width: 166mm

- Drive: gearbox with universal joint transmission system/gear transmission system

- Forming stations: 37

- Main motor power: 11kW

- Forming speed: 20-30m/min

- Finished slat width: 39mm, 42mm, 55mm

- Note: one machine can only produce one size of slat

- Uncoiler

- Feeding guide

- Roll forming

- Preheating

- PU foam injection

- Roll forming

- Leveling

- Fly saw cutting with servo motor

- Mechanical punching

- Runout table

Huazhong is committed to the innovation of roll forming machines and helping customers lower their costs and stay ahead in their competitive market.