Hot Air Shock Channel

Request a Quote

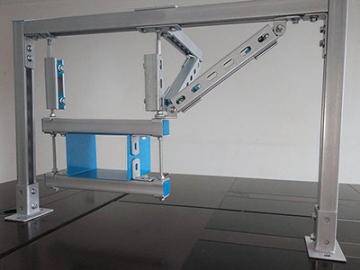

Vulcanization system for curing rubber profiles

JHL-43T-X Electrical heating

JGL-50C-X Gas heating

JGL-T/C-X Gas or electrical heating

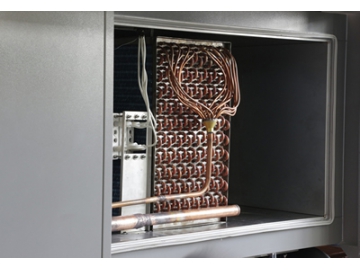

Hot air shock channel utilizes high-speed hot air to heat and cure the surface of rubber strips, effectively improving the surface quality of products. This equipment has a maximum heating temperature of 450˚C, and an effective heating zone length of 3m.

Application

Used for high-temperature curing of various rubber materials in automotive component manufacturing, rubber seal production, and cable manufacturing.

Features

- Roller drive system improves surface quality of products effectively.

- High air velocity enhances heat exchange efficiency.

Specifications

| Dimensions | L3700mm×W1000mm×H1500mm (subject to final design drawings) | |

| Profile Pass-through Aperture Height | Effective size above the roller: 100mm | |

| Conveyor Method | a. Non-driven roller conveyor. b. Active roller conveyor, with water cooling system to effectively prevent product adhesion to the rollers and avoid damage to the product surface. c. Belt conveyor. | |

| Conveyor Speed | 4~35m/min, variable frequency speed regulation | |

| Heating Method | Gas heating/electrical heating/gas or electrical heating | |

| Heating Temperature | Max. 450℃, common range: 250~400℃ | |

| High-temperature Fan | Stainless steel fan | |

| Hot Air Circulation Method | Inlet blowing towards the outlet, and outlet recirculation. | |

| Temperature Deviation Within The Channel | Longitudinal temperature difference is less than 10℃, with an accuracy of ±1℃. | |

| Door Opening | Pneumatic or manual opening | |

| Effective Vulcanization Length | 3000mm | |

| Inner Channel Material | T2.0mm stainless steel plate SUS430 | |

| Detection Device | Chain breakage detection | |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos