Pressure Nozzle Spray Dryer

The material is sprayed into fine mist by nozzle on the top of tower. Follow the heat wind, the material is dried. The machine's characteristic is high collection rate, no stick onto the wall, energy saving, high efficiency, especially applicable for heat sensitive material.

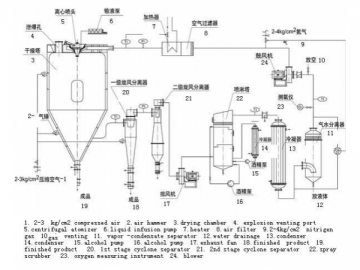

Descriptions for The Flow Chart:

The pressure spraying, granulating and drying mainly consists of a feeding system, drying system, dedusting system, heating system and electrical system, and each of the systems is composed of the corresponding equipments. The feeding system is composed of the mixing barrel, filter, diaphragm pump and spray gun. The ball-milled secondary slurry is transferred from the ball mill to the mixing barrel, extracted and delivered by the diaphragm pump through the filter, and then passed by spray gun to the drying tower. Slurry is sprayed by the nozzle into the drying tower for granulating and drying by three stages.

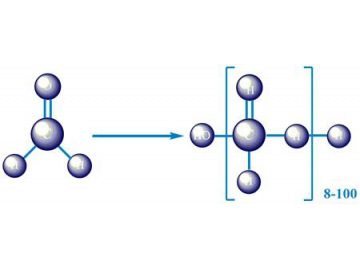

Atomization of Slurry:

Slurry is pressed by the diaphragm pump from the nozzle into the drying tower under certain pressure, with the energy of pressure converted into kinetic energy; slurry is sprayed upward from the nozzle to form a layer of high-speed liquid film, which is soon broken up into droplets. The size of atomized droplets is inversely proportional to pressure, while the capacity of nozzle directly proportional to the square of pressure.

Discharge of Particles and Powders:

The drying system is composed of the blower that supplies hot air to the drying tower, the drying tower and induced draft fan.

The dedusting system mainly consists of a high-efficiency cyclone separator, bag type dust collector and centrifugal fan. Fine particles and powders, together with dry air, are driven by the induced draft fan into the high-efficiency cyclone separator, and after effective separation, recovered in the collector drum at the bottom of separator, with the remaining exhaust gas containing little fine particles being drawn by the centrifugal fan into the bag type dust collector for re-dedusting and collection for harmless treatment; finally, exhaust gas is vented from the stack.

In addition, the heating system composed of electric heater and gas-fired hot air furnace supplies hot air for the drying tower, and the electrical system composed of electric control cabinet and field sensors mounted at the air inlet and material outlet is provided for monitoring and control of main points of the whole spraying, granulating and drying equipment to ensure normal operation.

Droplets Drying into Spherical Particles and Powders:

Droplets are delivered by hot air in mixed flow, and hot air enters the tower through the air distributor at the top cover, which generates a downward linear air flow; droplets are sprayed into the hot air flow upward and formed into spherical particles under the action of surface tension; meanwhile, droplets with large surface area are rapidly evaporated and dried, and finally shrunk into dry spherical particles and powders.

Features:

1. High drying speed, surface area greatly increased after atomization of feed liquid, 95%-98% water instantly evaporated in hot air flow, the time of drying only a dozen seconds to dozens of seconds; especially suitable for drying of heat-sensitive materials.

2. The final product is spherical particles with even granularity, high purity and good liquidity, solubility and quality.

3. Wide range of application and strong applicability to materials; this series can be used for drying with hot air and granulation with cold air according to material characteristics.

4. Simple and stable operation, easy for control and automation.

5.Because of different products have different drying technologies and particle rules, there is no single type of the spray drying machines that meet all kinds of different requirements. Now spray drying is still regarded as a kind of practical technology. The test is the base for correct model-selection. The machine equipped by our company is used specially for the carrying out the technological trial test of the materials. This kind of practical manner makes that we have completed many turn-key projects, such as: detergent powder, polymerized resin, white carbon,Mn3O4,soybean milk, lipase, sea cucumber Chinese traditional medicine and etc.

Food Industry:Fatty milk powder, protein, cocoa milk powder, subsitute milk powder ,egg white (yolk), food and plant ,oats ,chicken juice, coffee ,instant dissoluble tea ,seasoning meat ,protein ,soybean ,peanut protein, hydrolysate and so forth .Sugar ,corn syrup ,corn starch ,glucose .pectin ,malt sugar , sorbic acid potassium and etc.

Medicine: Traditional Chinese medicine extract ,ointment ,yeast, vitamin ,antibiotic, amylase ,lipase and etc.

Plastics and resin : AB, ABS emulsion, uric acid resin, phenolic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, poly-chloroprene and etc.

Detergent :common washing powder ,advanced washing powder ,soap powder ,soda ash ,emulsifier ,brightening agent ,orthophosphoric acid and etc.

Chemical industry :Sodium fluoride (potassium ), alkaline dyestuff and pigment ,dyestuff intermediate, Mn3O4, compound fertilizer ,formic silicic acid ,catalyst, sulphuric acid agent ,amino acid ,white carbon and so on.

Ceramic: aluminium oxide, ceramic tile material, magnesium oxide, talcum and so on.

Other: Calmogastrin, hime chloride, stearic acid agent and the cooling spraying.

Model & specs. 50 100 150 200 300 500 1000 Water evaporation capacity Kg/h 50 100 150 200 300 500 1000 Overall dimension(ф*H)mm 1600×8900 2000×11500 2400×13500 2800×14800 3200×15400 3800×18800 4600×22500 High-pressure pump pressure Mpa 2-10 Power Kw 8.5 14 22 24 30 82 30 Inlet air temperature ℃ 300-350 product water contents % less than 5 percent, and 5 percent can be achieved. collection rate % >97 electric heater Kw 75 120 150 When the temperature is lower then 200, the parameters should be calculated according to the practical condition. electricity steam Mpa Kw 0.5 54 0.6 90 0.6 108 hot air furnace Kcal/h 100000 150000 200000 300000 400000 500000 1200000

Attentions before Order:

Liquid name and property:solid contents(or water contents),viscosity,surface tension and PH value;

Dry powder density residual water contents allowed,particle size,and maximum temperature allowed.

Output: shift time daily;

Energy that can be available at user’s site: steam pressure, electricity properly,fuel of coal,oil and natural gas;

Control requirement: whether or not the inlet and outlet temperatures should be controlled. Whether the whole control system should be fully automatic or semi-automatic;

Powder collection requirement: whether it's necessary to use cloth bag filter and the requirement of the environment of the exhausted gas.

Other special requirements.