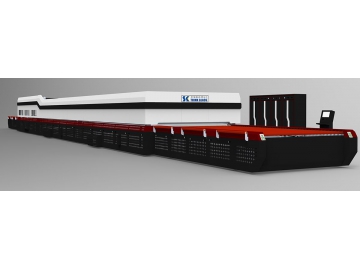

Dual-chamber Vacuum Oil Quenching Furnace

The dual-chamber vacuum oil quenching furnace is mainly applied to quench treatment for high-speed steel, die steel, Martensitic stainless steel, alloy steel, and titanium alloy, etc. Thanks to capability of gas quench and oil quench, our industrial heat treatment furnace allows for various production procedures selections and applications, and features fully automatic control.

Advantage

1. Although there are double chambers, our vacuum heat treatment equipment is still compacted with optimal layout for space efficiency.

2. Hearth of this vacuum quench furnace is heated as a whole unit. Internal charging trays are in stacking structure. Feeding speed is frequency regulated in slow-fast-slow mode, thus ensuring stable feeding and reduced time.

3. Unique air cooling system comes with built-in air channel for maximized cooling efficiency.

4. This dual-chamber vacuum oil quenching furnace is fitted with high efficiency external oil cooling circulation system for quench.

5. Oil tank has large capacity. Inside the tank, there are nozzles in various directions. As a result, there will be intense convection and turbulence during oil spraying, whereby catering to quench for large workpiece.

6. Vacuum degree and air cooling pressure are allowed to be adjusted to fit specific materials.

7. Simple operation and flexible input ensure stable performance. Manual and automatic operation can be switched readily. Moreover, alarms will be triggered automatically on failures of the dual-chamber vacuum oil quenching furnace.

Technical data| Model | |||||

| Rated feeding capacity | 50kg | 100kg | 200kg | 300kg | 400kg |

| Max. temperature | 1350℃ | ||||

| Temperature accuracy | ≤±5℃ | ||||

| Rated power | 50kW | 90kW | 120kW | 150kW | 180kW |

| Rated voltage of power supply | 380V | ||||

| Rated heating voltage | Depends on design Front transformer is available in every design. | ||||

| Max. vacuum degree | ≤6.67Pa (Empty furnace in cool status) | ||||

| Vacuum pressure rising rate | ≤50Pa/24h | ||||

| Working zone dimension (mm) | 300 × 300 × 400 | 300 × 300 × 500 | 450 × 400 × 670 | 450 × 400 × 850 | 600 × 600 × 1000 |

| Temperature control system | Shimaden programmable controller | ||||

| Vacuum control system | Rotary vane vacuum pump Roots pump | ||||

- Chemical Vapor Deposition Furnace

- Suspension Melting Furnace

- PSA Nitrogen Generator

Retrofit

1. PLC control and touch screen

2. Based on requirements on vacuum degree, oil diffusion pump can be added and maximal vacuum degree reaches 6.7×10-4 Pa.

Related Names

Double Chamber Vacuum Oil Quenching Furnace | Vacuum Furnace | Heat Treating Furnace