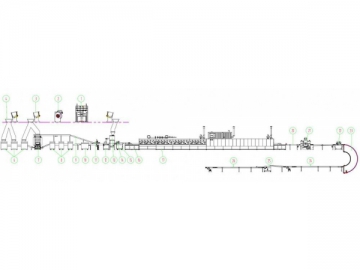

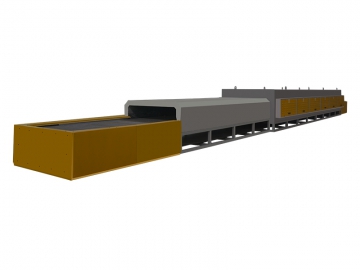

Mesh Belt Atmosphere Brazing Furnace

The mesh belt atmosphere brazing furnace is highly recommended for large volume production where stable quality, easy operation and dependable performance are primary concerns. This industrial brazing furnace has been proved to be perfect for sintering, brazing and quench with protective gas for mechanical parts applied to industries of electronics, household appliances and automobile.

Advantage

1. This atmosphere sintering furnace includes main mesh belt transmission system, hearth, driving device, heating furnace, mesh belt, cooling unit, protective gas device and pipeline, as well as cooling water pipeline and electric control system, etc.

2. The mesh belt atmosphere brazing furnace is welded by steel plate and profile steel. There is a Muffle made up of heat resistant stainless steel inside the furnace. This Muffle is specially treated for deformation prevention, resulting in prolonged service life. Thermal insulation materials adopt ultra-light fiber and premium refractory brick.

3. We place safety device on both heating unit and cooling unit on this stainless steel brazing furnace in order to facilitate operative protection.

4. Electric control involves the utilization of SSR control, which is highly distinguished by no noise generation and long service life. Moreover, there are alarms and failure indicators available to ensure production process to be smooth as shadows on the wall.

5. Our mesh belt atmosphere brazing furnace is well-suited for brazing of parts with thin walls made from stainless steel or carbon steel.

Technical data| Model | Power (kW) | Temperature (℃) | Hearth size (W×L×H) (mm) | Air consumption (m3/h) | Mesh belt width (mm) | Production capacity (kg) | Note 1. High temperature mesh belt furnace is applied to sintering, brazing and thermal quench. 2. Muffle adopts SUS310S heat resistant stainless steel. 3. Mesh belt is made from 1Cr25Ni20Si2 heat resistant stainless steel. 4. Protective gas normally is ammonia decomposition atmosphere. |

| 15 | 1150 | 100×1200 ×30 | 5 | 100 | 15 | ||

| 20 | 1150 | 100×1600 ×50 | 5 | 100 | 20 | ||

| 30 | 1150 | 150×2000 ×50 | 10 | 150 | 30 | ||

| 45 | 1150 | 150×3000 ×50 | 10 | 150 | 70 | ||

| 60 | 1150 | 200×3000 ×100 | 15 | 200 | 100 | ||

| 70 | 1150 | 200×3000 ×200 | 20 | 200 | 120 | ||

| 90 | 1150 | 300×3000 ×200 | 30 | 300 | 150 | ||

| 120 | 1150 | 400×3600 ×200 | 40 | 400 | 200 |

- Steel Belt Reduction Furnace

- Amorphous Alloy Powder Equipment

- Vacuum Induction Melting Furnace

Related Names

Continuous Mesh Belt Furnace | Induction Brazing Machine | Mesh Belt Conveyor Furnace